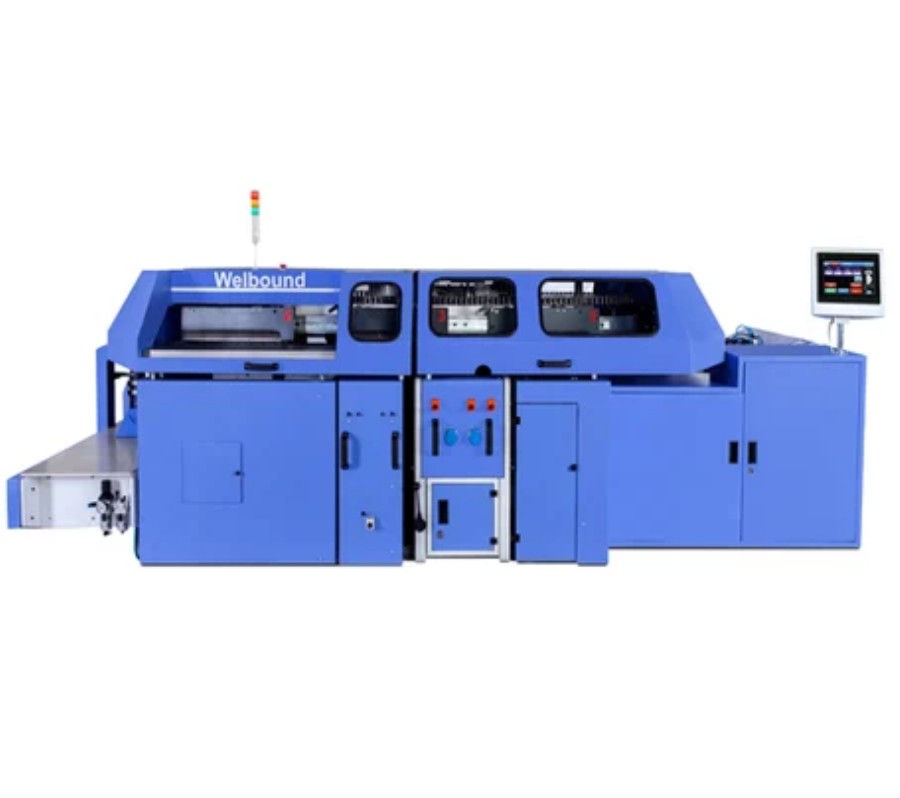

WB@ 4000

The WB@4000 is an advanced perfect binder developed by Welbound, designed to deliver high-performance and efficient bookbinding capabilities. This robust machine is engineered to meet the demanding requirements of commercial printing houses, binderies, and book manufacturers.

The WB@4000 boasts a powerful and versatile configuration, making it well-suited for a wide range of binding applications. With its advanced technology and features, it offers exceptional precision, productivity, and reliability.

The machine features automated functions that streamline the binding workflow, including automated book block measuring, spine preparation, and cover feeding. These automation features enhance efficiency, reduce setup time, and minimize human error, resulting in higher productivity and throughput.

Salient Features

- In-line feeding of gathered signatures or book block. Can be connected to a signature gatherer 12 calibrated book clamps with thickness indicators

- Centralised, single-action, clamp setting. Quick change-over of jobs

- Multi-function combination milling station with milling, notching, roughening, sanding and brushing of book spine

- 3 Roller glue tank with head and tail cut-off system plus accurate control of adhesive through doctor blade. Integrated Pre-melter, saving on space and energy. Digital temperature control with accuracy of +/- 1 Deg C

- Replaceable glue station on wheels that can be replaced with Cold Glue, PUR or any other type of adhesive or application system

- Gluing Options: Specially coated melter and applicators for PUR binding with Alta Pail® melting system and EP48 slot die from Nordson® Separate side gluing station with slanted gluing discs, providing a uniform, thin layer of glue, that stays within the front cover score area

- Automatic round pile type cover feeder with adjustable creasing attachment. Option of compressed air - vacuum generator or vacuum pump

- Moving type, cam driven, strong cover nipping station

- Down-hill and lay down delivery for feeding to the conveyor to trimmer

- Safety covers; built in safety systems with emergency stops; indicators for temperature, speed

- Control system with HMI providing all information on settings, speed, production data, energy consumption, and stoppage and maintenance warnings. Ability to send information through email/ SMS

Technical Data

| Mechanical Speed | 2300 Min - 4000 Max cycles/hour |