For print operations handling time-sensitive publications, binding is not a finishing step. Instead, it is a point of risk. Vidya Bharati Press discovered this early. As a result, their decision to invest in a high volume book binding machine was driven by a simple question: Can we meet deadlines every single day without exceptions?

A Press Built on Purpose, Not Volume Alone

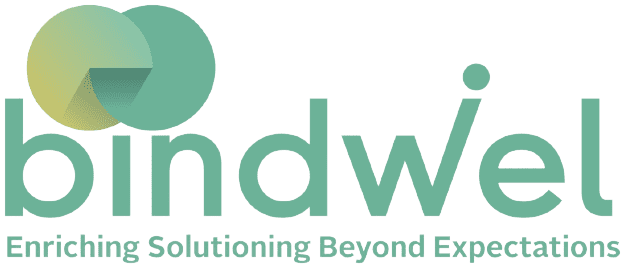

Vidya Bharati Press, founded by the Sri Sringeri Sharada Peetham Trust, operates in Bengaluru with a focused mandate—printing religious books, magazines, and invitations that are distributed through bookstalls of branch mutts and book houses.

The operation is not high volume in the traditional sense. However, expectations around quality, discipline, and delivery are uncompromising.

Their 3,200-sq-ft facility houses:

- Single, double, and four-colour Heidelberg offset presses

- Polar cutting system

- Printograph book stitcher

- Shoei folding machine

- Adast guillotine cutter

Yet, despite a capable print floor, binding had become the limiting factor.

The Problem Wasn’t Printing. It Was Finishing.

Before installing the Bindwel BW@2500 V24, the press could bind fewer than 1,000 books per day. As a result, this created pressure during peak schedules when multiple titles had to be bound and dispatched together.

A spokesperson from the press explained to PrintWeek:

“Earlier we were only able to produce less than 1000 books per day, but now production has increased to 2000–2500 books per hour.”

The shift was not incremental—it was structural.

Why a High Volume Book Binding Machine Was Non-Negotiable

Vidya Bharati Press did not need experimental technology. Instead, they needed a high volume book binding machine that could:

- Operate continuously

- Deliver uniform spine quality

- Avoid rework caused by page lifting or adhesive inconsistency

- Handle full-day schedules without downtime

The BW@2500 V24 was selected specifically for these reasons.

What Changed After Installation

Once operational, the Bindwel BW@2500 V24 became the backbone of daily dispatch planning.

Key improvements included:

- Production output increased to 2,000–2,500 books per hour

- Up to 20,000 softcover books produced in a single day

- Binding and dispatch of all titles within one working day

The press confirmed:

“We were supposed to bind and dispatch all titles in a single day, and we were able to do this with the Bindwel machine, and the timeline was met.”

As a result, this reliability reshaped internal scheduling.

The Features Of High Volume Book Binding Machine That Solved Real Problems

Rather than listing specifications, Vidya Bharati Press highlighted functional outcomes. This approach reflected daily production needs.

In an official statement to PrintWeek, the press noted:

“We find the production speed and technical support provided by Bindwel the most valuable.”

Two features stood out:

FPLP Gadget

The First & Last Page Locking (FPLP) gadget addressed a recurring issue where the first or last page would lift along with the cover when opening the book—especially noticeable in religious publications with frequent handling.

As a result, this eliminated the problem without additional stitching.

Adhesive Consumption Control (ACC)

The Adhesive Consumption Control system helped regulate glue usage across varying book thicknesses, reducing wastage and maintaining consistency.

Consequently, the press confirmed that adhesive consumption is now “kept in check.”

Accuracy at Scale, Not Just Speed

Speed alone was never the goal.

However, the introduction of a high volume book binding machine allowed the team to commit to timelines with confidence. They knew that:

- Every spine would hold

- Every title would be consistent

- Every dispatch window could be met

This predictability mattered more than peak output numbers.

Service Support as Part of the Equation

Beyond the machine itself, Vidya Bharati Press emphasised the role of Bindwel’s technical support. Because, this support played a consistent role in daily operations.

As a result In their statement, they confirmed satisfaction with:

- Installation process

- Ongoing technical assistance

- Responsiveness when required

Because, for a not-for-profit operation, service reliability was not optional—it was essential.

What High Volume Book Binding Machine Means for Similar Print Operations

For presses handling:

- Religious books

- Educational publications

- High-volume softcover titles

Therefore, a high volume book binding machine is not about expansion. Instead, it is about control with consistent output.

Vidya Bharati Press demonstrates that even facilities with modest floor space can achieve industrial-grade output when post-press decisions are made deliberately.

High Volume Book Binding Machine That Keeps Promises

The Bindwel BW@2500 V24 did not change what Vidya Bharati Press prints.

However, it changed how confidently they deliver.

By strengthening their bindery, the press removed uncertainty from the final stage of production—where deadlines either hold or collapse.

Therefore, for operations where every book matters, that difference is decisive.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel for more inspiration and insights on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.