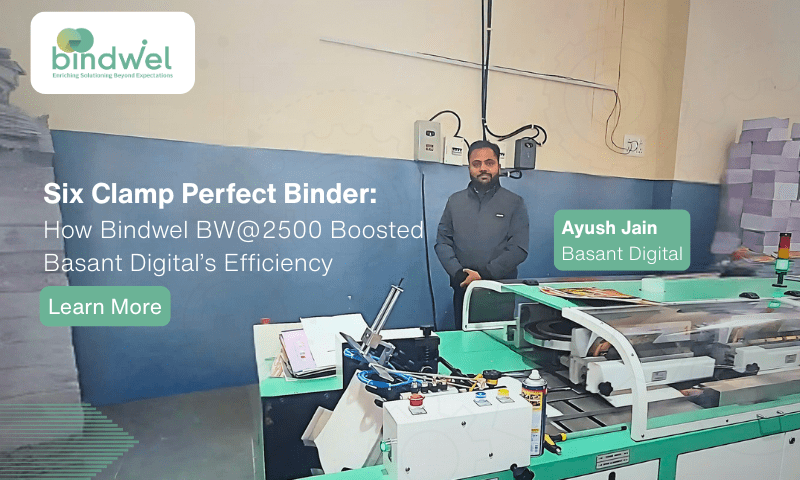

Can a binding machine truly redefine a publishing business? For Basant Digital Solutions, also known as Vardhman Books in Meerut, the answer lies in their investment in the Bindwel Six Clamp Perfect Binder BW@2500.

This compact yet powerful model has not only solved their outsourcing woes but has also transformed production speed, quality, and business opportunities.

🏢 About Basant Digital Solutions & Vardhman Books

With a sprawling 24,000 sq/ft factory and a dedicated team of 100 people working in two shifts, Basant Digital has earned a strong reputation in the educational and children’s book publishing industry.

The group has over 12 years of experience and is behind well-known titles like the Infinity and Neo Star book series. Their philosophy is simple but firm—deliver top quality on time, every time.

Beyond books, the group has expanded into innovative packaging solutions with Basant Packers, offering customized and sustainable packaging services for diverse industries. Together, these units drive a turnover of INR 50 crore, making Basant a trusted name in the publishing and packaging landscape.

⛔ The Challenge: Rising Demand, Outsourcing Bottlenecks

Before the Bindwel BW@2500, Basant relied on the WB@2000, another proven Bindwel solution. But as demand surged, the printer was forced to outsource additional binding work.

This created three pressing challenges:

- Quality issues with outsourced binding.

- Missed schedules that risked customer trust.

- Escalating costs of external jobs.

Ayush Jain, owner of Basant Digital, realized that relying on outsourcing was no longer sustainable. The business needed a next-generation, in-house solution that could handle volumes with consistent precision.

🚀 The Solution: Bindwel Six Clamp Perfect Binder BW@2500

The answer came in the form of the BW@2500 Six Clamp Perfect Binder—a compact yet high-performance model designed for publishers aiming to balance efficiency with quality.

Key features that tipped the scales for Basant include:

- Six calibrated book clamps traveling in an oval-shaped path with thickness indicators for quick, precise setup.

- Three-roller spine gluing system with reverse spinner and calibrated cut-offs for clean, durable binding.

- Separate side gluing station for a thin, even adhesive layer that enhances finish quality.

- Automatic cover feeder with ornamental creasing and accurate cam-based nipping.

- Smart HMI control system with intuitive data and safety monitoring.

- No Book–No Cover safeguard for error-free operation.

Together, these innovations make the BW@2500 not just a binder, but a future-ready investment for Indian publishers.

📈 The Impact: Faster Turnarounds & Quality Uplift

The real proof came in production. With the Six Clamp Perfect Binder in place, Basant Digital was able to:

- Successfully entered the Mumbai market, serving commercial printers and canvassers with short-run publication needs.

- Deliver children’s books on time and with consistently high quality.

- Execute massive projects like the Pikaso book series—a two-lakh run where 40,000 books were produced in a single day to meet an impossible deadline.

The Six Clamp Perfect Binder allowed Basant to scale seamlessly while maintaining its promise of quality and punctuality.

🛠️ Overcoming Odds: Service During the Kumbh Mela

A true success story isn’t complete without a test of resilience. During the Kumbh Mela, when all routes in and out of Meerut were blocked, Basant urgently needed their machine serviced before a deadline.

Despite the odds, Bindwel’s service engineer reached the facility and made the Six Clamp Perfect Binder BW@2500 operational on time.

This not only saved the project but reinforced Bindwel’s reputation for unmatched after-sales support—a factor as important as the machine itself.

💬 Customer Testimonial: Ayush Jain Speaks

Ayush Jain, owner of Basant Digital Solutions, couldn’t be more satisfied:

“Our focus is top quality and on-time service of our publications. The latest installation from Bindwel is compact, high-performance, and has transformed our workflow. It has opened up exciting new business opportunities.”

On children’s book production, he adds:

“We are very happy to make children’s books on time and with the best quality on every project.”

📚 Lessons for Indian Print Businesses

The Basant Digital journey is a lesson for printers across India:

- Six Clamp Perfect Binder BW@2500 = higher efficiency, better quality, faster deliveries.

- In-house control eliminates dependency on outsourcing.

- Indian-made technology with local support ensures reliability in even the toughest situations.

For publishers of educational and children’s books, as well as commercial short-run jobs, the BW@2500 sets a benchmark in modern bookbinding.

✨ Six Clamp Perfect Binder: Scaling with Confidence

By investing in the Bindwel Six Clamp Perfect Binder BW@2500, Basant Digital Solutions has elevated itself from a regional leader to a nationally competitive publishing powerhouse.

The binder has proven to be more than a machine—it is a strategic growth partner that strengthens workflow, quality, and customer confidence.

As Indian publishing evolves, printers like Basant show how smart technology investments pave the way for sustainable and scalable growth.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production