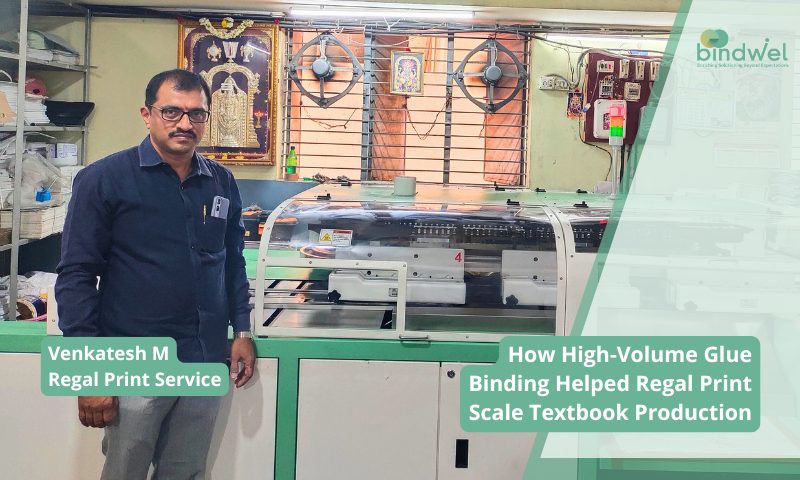

Speed meets precision at Regal Print Services, Bengaluru. In a feat of sheer turnaround efficiency, the company completed 50,000 softcover textbooks in just five days. The secret? High-volume glue binding with the Bindwel BW@2500 Epic.

About Regal Print Services: Legacy of Trust and Scale

Operating from a 4,500 sq. ft. facility in Bengaluru, Regal Print Services has built a robust reputation in textbook and private publication printing. With five offset presses, the firm caters to the growing needs of educational institutions and publishing agencies.

But success brings volume—and volume demands speed.

The Challenge: Bottlenecks in Book Finishing

Before the Bindwel upgrade, Regal Print was grappling with delays in its finishing department. Although printing operations were efficient, the bindery was slowing things down significantly.

“Beforehand, there was a bottleneck,” shared Venkatesh M of Regal.

This persistent delay affected turnaround time, leading to missed windows and strained workflows.

The Game-Changer: BW@2500 Perfect Binder

In early 2025, Regal Print installed the BW@2500 Epic 6-clamp perfect binder from Bindwel—a machine specifically engineered for high-volume glue binding with intelligent automation.

“Its production speed and quality have been fantastic,” said Venkatesh M.

Key Technical Features:

- Six calibrated oval-path book clamps

- Intelligent MIS system for real-time data and diagnostics

- Pre-pasting and powerful nipping station for perfect book finish

- 3-roller spine gluing with squeeze-out wiper and notch cleaner

- Inline cover feeding with ornamental creasing

Altogether, these features offer unmatched speed, precision, and reliability.

The Result: 50,000 Textbooks in 5 Days

One standout project was with Jeevith Publications – Subash Agency, where Regal delivered 50,000 PUC textbooks across multiple titles.

Thanks to BW@2500’s 2,500 cycles/hour capacity, this massive order was turned around in just five days—all without compromising quality.

“The versatility of the Bindwel helped,” said Venkatesh.

Such performance has elevated Regal’s position as a reliable, high-speed textbook producer.

Trouble-Free Operations & Seamless Support

Regal was equally impressed by the continued support Bindwel extended during and after installation.

“There are no service issues, no quality issues and no loss of production time,” said Venkatesh M.

The machine’s durability and Bindwel’s responsiveness have allowed Regal to operate at full capacity without disruptions.

Enhanced Production Efficiency

With BW@2500, Regal Print gained:

- Fast changeover with single-knob clamp adjustments

- Smart automation through touch-based HMI

- Reduced wastage and glue control with ALC (Adhesive Layer Control)

- Higher book finish standards via driven side glue and powerful nipping

This high-volume glue binding setup has become Regal’s cornerstone for rapid scalability and reliable production.

Industry Perspective: A Binding Solution Made in India

“At Bindwel, we are committed to pushing the boundaries of innovation in book binding, ensuring precision, quality, and efficiency,” said P Sajith, MD of Bindwel.

The BW@2500 installation at Regal Print reflects Bindwel’s broader mission—to deliver world-class, Indian-made solutions that can rival any global competitor.

Regal’s Next Chapter Begins with Bindwel

From battling finishing bottlenecks to delivering massive textbook orders on tight deadlines, high-volume glue binding with BW@2500 has completely transformed Regal Print’s operations.

With flawless finishing, zero downtime, and faster throughput, Regal is now confidently positioned to meet the growing demands of educational printing.

✨ Follow us for more real-world success stories from India’s fastest-growing print businesses.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.