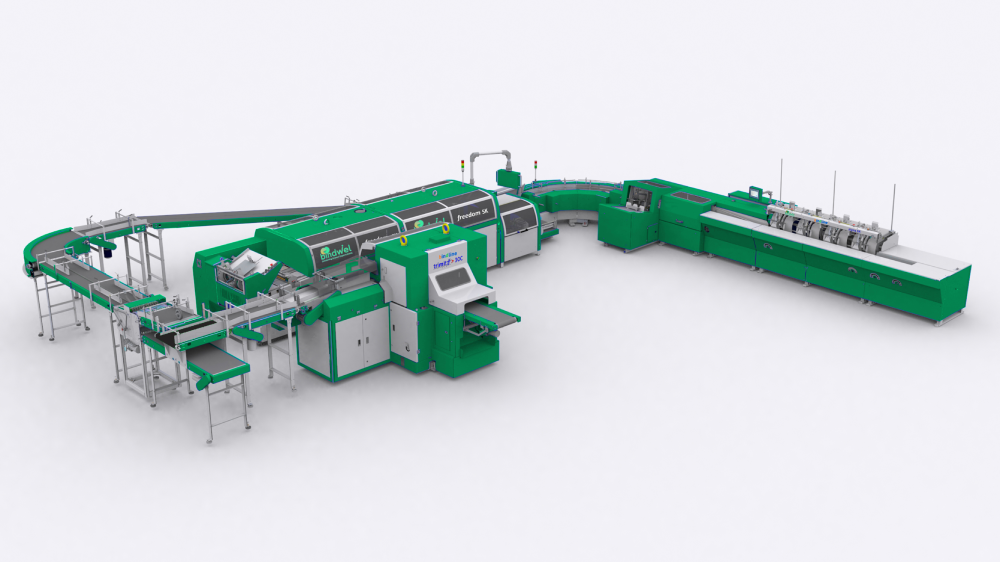

Inline Binding Systems

Seamless Book Production from Gathering to Final Trim

“Going inline with Bindwel meant fewer touch points and faster dispatch. From gathering to trimmed book, everything now flows like a single machine.”

- Yudhistira Ghalia, Indonesia

“Blue Chip fits perfectly into our digital print workflow. Reliable, compact, and extremely efficient. Our operators love the ease of use!”

- Ashish Mehta, Pune

Bindwel – Inline Binders for End-to-End Book Production

Inline binding systems connect signature gathering, perfect binding, and trimming into a single, continuous workflow. They eliminate repeated manual handling, reduce errors, and dramatically increase throughput – especially for textbooks and high-volume commercial work.

Bindwel’s inline solutions, Freedom Bindline and EKAM, are engineered around this philosophy:

- consistent book quality

- lean use of space and energy

- production data visibility at every stage

Whether you run a large textbook plant or a fast-growing export unit, Bindwel inline systems help you move from islands of machines to one connected book factory.

Our Inline Binding Machine Offerings

Bindwel provides a versatile portfolio of PUR binding solutions suitable for small, medium, and large printing environments

- Up to 5000 books/hour when connected inline

- Integrated HMI with production data, speed, and stoppage information

- Custom conveyors between units for true end-to-end flow

EKAM – Lean Inline Textbook Line

EKAM is a new-generation inline system inspired by FMCG-style production lines and designed for the most common textbook formats.

- Standardized range of book sizes for maximum efficiency

- Up to 50% floor space saving compared to conventional lines

- Reduced complexity and components, lower energy consumption

Key Features of Bindwel Inline Binding Systems

- End-to-End Integration

Connects gatherer → binder → trimmer so book blocks move automatically without manual stacking or re-feeding.

- Higher Throughput, Lower Handling

Inline layouts improve productivity and reduce labor and handling errors compared to stand-alone machines.

- Consistent Quality Across Processes

Standardized spine preparation, gluing and trimming ensure uniform book blocks, crucial for large textbook and export orders.

- Future-Ready Options

Compatibility with PUR, barcode/QR-based integrity, and camera systems for signature control where required.

- Centralized Control & MIS

Centralized Control & MIS

Why Choose Bindwel Glue Binding Machines

Specialists in the Complete Book Line

From Signa gatherers to Freedom binders to Trimit three-knife trimmers, Bindwel designs and supports the entire book path – not just one machine.

Designed for Textbook Realities

EKAM and Freedom Bindline are tuned to the standard textbook formats and volumes that dominate Indian and export markets, ensuring practical speeds and reliable performance.

Lean Footprint, Lower Energy per Book

Inline systems consume less space and, with optimized drives and premelters, achieve low energy per book compared to multiple disconnected units.

Consultative Implementation

Bindwel’s team helps redesign plant layout, material flow, and job planning so you actually realize the benefits of going inline—not just install another machine

Frequently Asked Questions (FAQs)

What is an inline binding system?

An inline system links gathering, perfect binding, and trimming so books move continuously from one process to the next without manual re-handling. This improves speed, consistency, and safety compared to separate offline units.

When should a printer move from offline to inline?

Inline makes most sense when you:

- produce large volumes of similar formats (e.g., textbooks),

- face bottlenecks in manual movement between machines, or

- need predictable turnaround times for export or large tenders.

What’s the difference between Freedom Bindline and EKAM?

- Freedom Bindline – high-speed, flexible line built around Signa 5K + Freedom binder + Trimit trimmer, suitable for a wider variety of book formats and commercial work.

EKAM – lean, standardized line optimized for the most common textbook formats, with a strong focus on space saving and cost efficiency.

How do I decide the right configuration for my plant?

The ideal setup depends on:

- share of textbook vs. trade work

- typical run lengths

- existing gathering/printing equipment

- space and energy constraints

Bindwel typically does a layout and throughput study before recommending Freedom Bindline, EKAM, or a hybrid.