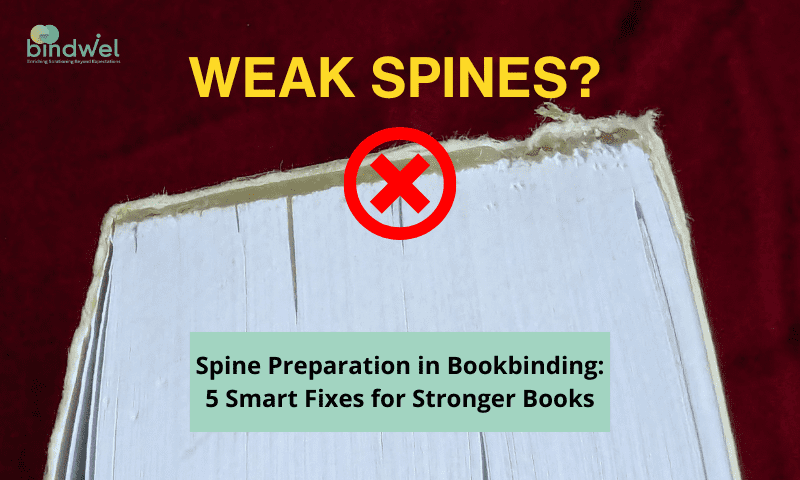

Spine Preparation in Bookbinding is where most binding failures begin. Even when your print quality is flawless, weak spines and page dislodgement can ruin the entire job. Poor milling, inconsistent glue, or ignoring paper chemistry doesn’t just cause rework—it leads to customer complaints that damage credibility.

This is the invisible stage where a book’s durability is decided. In this blog, we’ll explore why spine-prep mistakes happen, how to recognize them, and the proven shop-floor fixes that guarantee stronger, longer-lasting books.

The Critical Mistake: Adhesive & Spine-Prep Mismatch

Most binding breakdowns happen because spine preparation and adhesive selection don’t align. This mismatch typically arises from:

- Inconsistent milling and notching depth.

- Blunt tools that don’t create proper glue channels.

- Using the wrong adhesive for coated stocks, digital toners, or short runs.

- Poor pot control—temperature or viscosity swings.

- Running in environments outside RH and moisture targets.

Together, these factors create weak spines that fail silently until the book reaches a reader.

Symptoms of Spine-Prep Problems

If you see these, it’s a spine-prep red flag:

- Insufficient glue penetration into the spine.

- First-page and last-page lift after a few uses.

- Blowholes or voids in the glue line.

- Brittle, cracking spines that snap under stress.

- Glue strings during production runs.

Each symptom points back to one cause: a breakdown in milling, glue, or environment control.

Quick Wins to Fix Adhesive & Spine Prep Issues

- Service the milling/notching station: log depth settings for every job, sharpen or replace blades regularly.

- Match adhesive to stock: coated, uncoated, synthetic — don’t compromise. Use a one-grade adhesive policy for spine + side glue wherever possible.

- Log pot temperature & viscosity: check every batch and record it.

- Clean glue pots on a scheduled routine to prevent contamination.

These small steps prevent most binding complaints.

Pro Practices for Long-Term Reliability

- Introduce a 5-pull / 5-flex test: bind → rest 20–30 minutes → test pull and flex on first-off copies.

- Discipline your floor around Relative Humidity (RH): keep it at 40–55%.

- Check moisture balance: text at 5.5–6%, boards at 6–8%.

- Calibrate nipping pressure and dwell time per stock type and save presets in your machine.

- Train operators to recognize “low spine glue shine” as a warning sign.

These practices turn guesswork into controlled, repeatable processes.

The First-Off Audit Routine for Spine Preparation in Bookbinding

Spine preparation errors can be stopped cold if you check the right things in the first-off audit. Every operator should verify:

- Milling and notching depth settings logged and correct.

- Adhesive temperature within tolerance.

- Side-glue width adequate for the block.

- Spine glue penetration visible and uniform.

- First-off book passes the 5-pull / 5-flex test.

This five-point check prevents entire batches of weak books from reaching packing.

Spine Preparation in Bookbinding: What to Measure

If you want spine-prep quality to stay consistent, track these metrics:

- Pull-test pass rate on first-off books.

- Adhesive grade vs. failure incidence.

- Temperature stability (std. deviation) per run.

- Rework percentage due to page lift or spine cracking.

Visible metrics make operators accountable and give management real control.

Why This Matters Now

Readers judge a book by how it feels when opened and used. If pages start falling out, the print quality is irrelevant—the book has failed.

With shorter runs, tighter margins, and more coated or specialty papers in play, spine preparation in bookbinding is no longer optional discipline—it’s survival.

Bindwel’s Advisory Approach to Spine Preparation in Bookbinding

Bindwel’s post-press advisory helps printers and publishers by:

- Auditing spine-prep consistency on the shop floor.

- Training teams in adhesive selection and application recipes.

- Running live clinics where operators practice first-off tests.

Our goal: to make your books last longer, look better, and generate fewer costly complaints.

Lasting Books Start with the Spine

Every book depends on its spine. Get it wrong, and your readers will remind you in the harshest way possible—with returns and rejections. Get it right, and you’ve built trust that lasts beyond a single print run.

Spine preparation in bookbinding is where true quality is forged.

👉 Want practical fixes like this delivered straight to your feed? Follow Bindwel for more shop-floor strategies, binding know-how, and insider expertise.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production