In the fast-paced world of digital printing, precision isn’t a luxury — it’s the foundation.

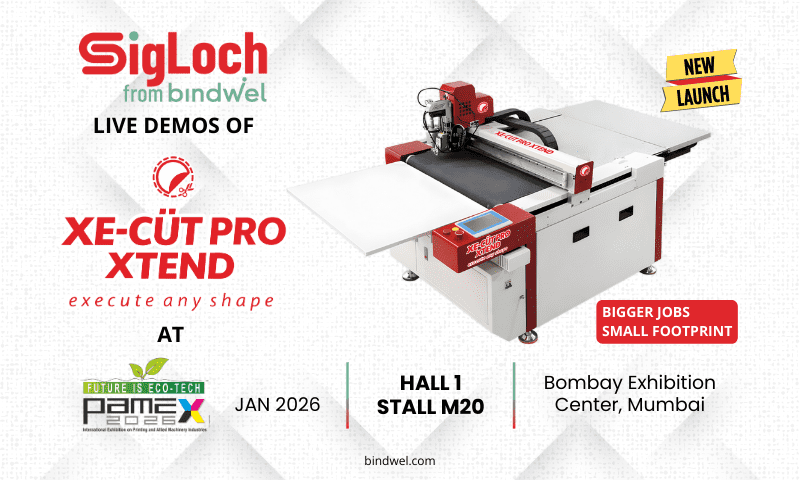

That’s where the SigLoch XE-CÜT Pro, a Digital Flatbed Cutter with Oscillating Knife, takes center stage. Designed for short-run packaging and sample-making, it’s compact, powerful, and locally engineered to meet modern post-press needs.

In this first episode of our SigLoch XE-CÜT Pro Explainer Series, our technical head breaks down how the V-Groove and Oscillating Knife tools redefine flexibility, efficiency, and finish quality for every print shop.

Why the Digital Flatbed Cutter with Oscillating Knife Became Essential

Short-run custom jobs and sample-making are now everyday realities. But traditional die-cutting couldn’t keep up — it required expensive dies, long setup times, and constant operator intervention.

The Digital Flatbed Cutter with Oscillating Knife bridges that gap. It delivers clean, precise cuts, folds, and grooves without needing separate setups.

SigLoch designed the XE-CÜT Pro to merge power, control, and versatility into a single compact machine.

The Oscillating Knife: Sharp, Fast, and Controlled

At the heart of this digital flatbed cutter lies its most dynamic feature — the Oscillating Knife.

Unlike fixed blades, this knife moves up and down rapidly, slicing through even dense materials like foam board, Kappa board, corrugated sheets, and gasket rubber.

“It’s not just about power — it’s about control. Every oscillation ensures precision, even at full speed.”

— Project Technical Head, SigLoch

This high-frequency motion eliminates burns or compression marks and ensures consistent quality.

For digital printers, that means faster turnarounds, sharper edges, and minimal material waste — especially in short-run packaging or rigid box prototyping.

The V-Groove Tool: Where Ideas Take Shape

If the oscillating knife adds strength, the V-Groove tool adds structure.

This feature helps create foldable edges on rigid materials like sunboard, grey board, or KT board, making it ideal for luxury boxes and presentation kits.

Controlled through the same touchscreen interface, the V-Groove tool maintains precise depth without damaging the outer layer.

It’s what gives premium packaging that clean, seamless fold — a finish that looks hand-crafted but is fully automated.

“The V-Groove tool lets creativity take shape — literally.”

— Project Technical Head, SigLoch

Together, the V-Groove and Oscillating Knife tools showcase the power of the Digital Flatbed Cutter with Oscillating Knife — blending creative design and industrial precision in one smart system.

Precision in Motion: Two Heads, One Perfect System

Both tools operate under pneumatic control and camera-based registration for ±0.1 mm repeat accuracy.

With built-in QR-code recognition, the system reads job data instantly, ensuring quick, error-free setup.

Auto-feeding, vacuum clamps, and smart sheet separation make continuous runs possible — allowing one operator to handle multiple short-run tasks with ease.

That’s the efficiency today’s digital workflows demand.

What Makes the SigLoch XE-CÜT Pro Stand Out

Here’s what separates SigLoch XE-CÜT PRO – the Digital Flatbed Cutter with Oscillating Knife from conventional systems:

- Handles over 20 substrates, from 100 GSM paper to 6 mm boards.

- Combines cutting, kiss-cutting, creasing, and V-Grooving in one pass.

- Compact and energy-efficient design for any print setup.

- Built in India with reliable service, affordable spares, and local expertise.

Printers can now expand into short-run packaging, mock-ups, and creative digital finishing — without dies, delays, or downtime.

Smarter Finishing for the Digital Era

The SigLoch Digital Flatbed Cutter with Oscillating Knife isn’t just another finishing system — it’s a bridge between creativity and production.

Whether for luxury invitations, premium packaging, or sample mock-ups, it helps printers deliver fast, precise, and profitable results.

Supported by Bindwel’s strong local service network, it ensures smooth operations and minimal downtime — so your ideas never have to wait.

See It Live at Print Pack Innovation Indore

Visit: Hall B | Stall A20

Your digital workflow deserves this upgrade.

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production