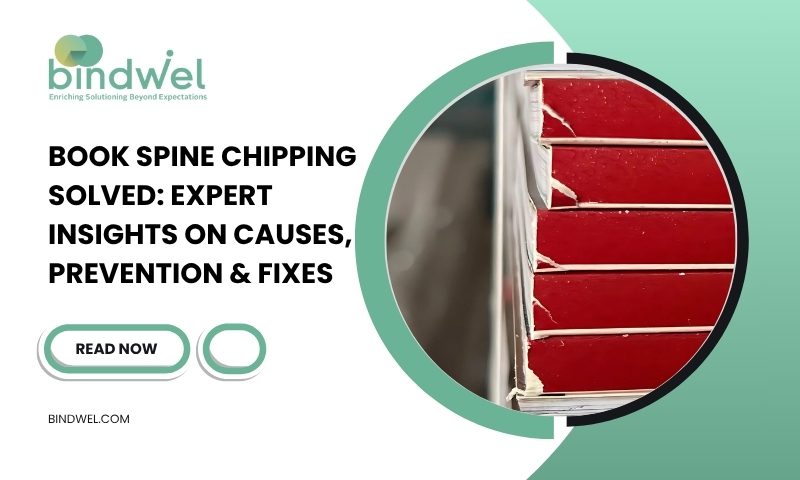

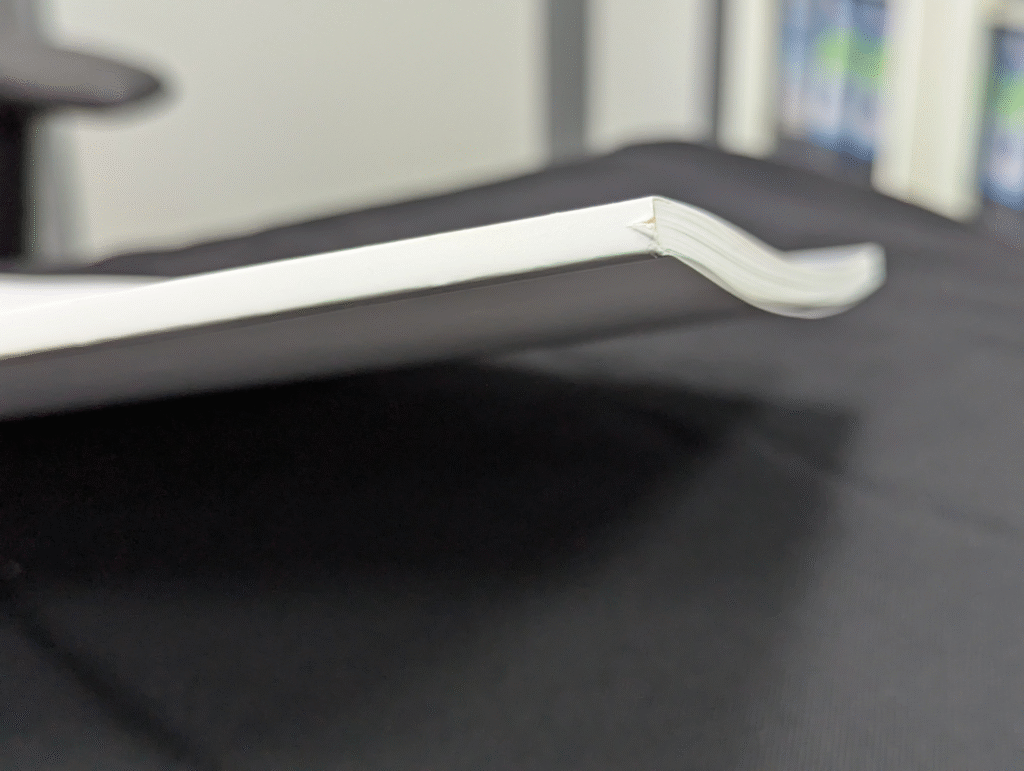

Book finishing is where good books become great. But for many post-press professionals, one persistent issue ruins it all: spine chipping. That unsightly tear or flaking along the spine can destroy the look and structural integrity of a book—especially under scrutiny from export clients or bookstore shelves.

Recently, a customer reached out to Bindwel with concerns over severe spine chipping on books trimmed on their existing three-knife trimmer setup. Our CTO, Suresh Nair, who is known to many of our customers as a Book Scientist – responded not with vague advice, but with surgical precision—unpacking every factor, right from the fibre structure to blade motion.

Here’s the complete insight so you can identify, control, and eliminate this issue from your shop floor.

🧠 What Is Spine Chipping?

“Spine chipping” refers to the damage or tearing observed at the edge of the book spine after trimming, particularly on three-knife trimmers (TKT). It’s a subtle but serious defect that can spoil both the look and structural integrity of the book—especially when stacked in retail or sent to global markets. This issue stems from a mix of:

- Cover material behavior

- Blade sharpness and motion

- Spine glue distribution

- Ambient moisture conditions

It’s not just cosmetic—it affects usability, durability, and market acceptance.

🔢 Cover Material Type

- Non-laminated covers are more vulnerable to chipping.

- Multi-layered laminated (couched) covers also tend to delaminate or tear when trimmed.

- The solution: Prefer covers with proper lamination suited for trimming.

Multi-layered Laminated (Couched) Covers: A Hidden Culprit

These are thick, bulky covers made of loosely pressed paper layers. Their sponge-like structure avoids calendering (compression under heat rollers) to allow easier creasing. But this comes at a cost:

- Too soft to resist blade pressure

- Easily crack during creasing or trimming

- Often non-laminated, making fibres more exposed

“When you try to crease, it will crack. That’s why they don’t press it so much—it feels bulky, but the fibres inside are loosely packed.”

Takeaway:

If using couched cover material, either laminate it, coat it better, or reinforce the trimming with the help of a Spine-supporting Knife.

🔮 Lamination: A Blessing and a Challenge

Lamination acts as an external protective skin. This film acts as a barrier to prevent fibre tear during trimming. But if poorly applied or omitted, it results in chipping.

Today because of sustainability pressure, stakeholders are opting for various types of coatings instead of laminations due to plastic waste concerns.

“Without lamination, in 100% cases, you need Spine-supporting Knife.”

🔧 Spine Quality & Stack Support

Spines should be square but sometimes they are slightly rounded at the edges. When such books are stacked for trimming, the gap between two spines should not exceed 0.5 to 0.8 mm. If one spine lacks firm support besides, it tears or chips during trimming. Reference: This is why saddle-stitched/ centre-stitched books are never trimmed in stacks.

Mid-Spine Chipping:

If the spine cracks midway, it’s often because there’s no glue behind that spot:

- Glue gap due to poor milling

- Cover separation

- the gap between two spines

“This often happens when the glue is patchy or the spine lacks support besides.”

Stacking books for trimming without support below can also cause this problem. Saddle-stitched books avoid this by trimming one at a time.

🌊 The Moisture Angle

Moisture content in covers must stay between 5.5% and 6%. Below that, due to dry weather or thermal lamination, the cover becomes brittle which is:

- More prone to tearing

- Paper shrinks and contracts

- Increased stress on cutting point

Verify moisture levels using a paper moisture meter, especially in seasonal shifts.

🧠 Knife Quality and Setup

Trimming knife angle and sharpness are crucial:

- 20°–22°: Sharper cut but dulls faster

- 22°–24°: Durable but can increase vibration and tearing

- Carbide knives: Carbide knives are the gold standard. Though expensive, they maintain sharpness longer and provide cleaner cuts.

- The solution: Use HSS or carbide blades with correct angles, and ensure timely regrinding.

Regrind frequently, monitor knife holder movement, and ensure cutting stick alignment.

💡 The Reality Check: “Why Now?”

A question Suresh often hears from customers: “It wasn’t happening earlier—why is it now?” The answer lies in subtle variations—material batches, moisture changes, or cover type changes. The spine support issue becomes visible only when the combination of these factors crosses a tolerance threshold.

🛠️ The Solution: Bindwel’s Spine-Supporting Knife Attachment

To address this common pain point, Bindwel’s Trimit 30C TKT machine now comes with an optional spine-support knife.

- It acts as a pressure counter besides the spine during trimming.

- Ensures that even top books in a stack have uniform support.

- Compensates for all the above variables—material quality, stack gap, even inconsistent moisture.

In Suresh’s words, “It’s a well thought out design, which is very effective in instantly raising the aesthetics and reliability of your output.”

🔹 Mandatory Spine-supporting Knife (SSK) in Certain Cases

If you’re working with:

- Aqueous coated covers

- Sponge-like couched boards

- Cross-grain trimming

- Thin book stacks

…you must use a spine-supporting knife. This acts as a counter-pressure tool besides the spine of the book, ensuring clean cuts.

📆 Before Production: Trial and Test

Here’s the SOP recommended by Suresh:

- Bind a few dummy books which exactly mimics your actual setting

- After printing give 24 hours before lamination or any coating

- Trim with your actual settings

- If you notice chipping:

- Check if your Trimmer has Spine-supporting Knife

- Switch to laminated cover

- Change cover material

This simple testing saves money, time, and customer complaints.

🛍️ Final Thoughts: Spine Chipping Is a Symptom, Not the Disease

Spine chipping often appears like a trimming problem, but it rarely starts there.

It’s a downstream result of:

- Poor cover material choice

- Rushed lamination

- Incorrect knife setup

- Glue inconsistencies

- Low-moisture ambient conditions

Machine solutions like the Bindwel Trimit 30C with spine- supporting knife help mitigate the outcome, but understanding the root cause makes your entire process better.

“Ultimately, it’s not about doing extraordinary things—it’s about doing the ordinary things extraordinarily well.”

🚀 Ready to Solve Spine Chipping Once and for All?

If you’ve faced trimming issues like chipping, blunt cuts, or delamination, our team at Bindwel is ready to help.

✉️ Whatsapp or Mail us to get in touch for a one-on-one diagnosis.

Whatsapp: wa.aisensy.com/+917676377674

Mail: [email protected]

📊 Or follow us for more deep-dive guides, shop floor success stories, and machine innovations that work.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.