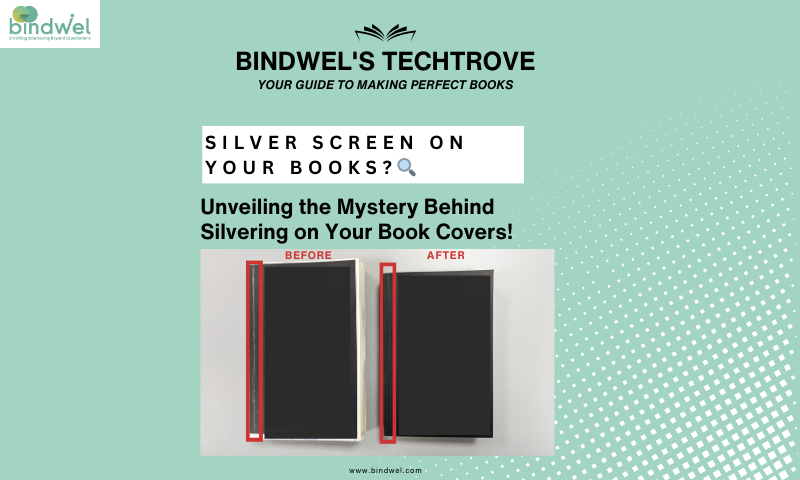

Silver Screen on Your Books? Unveiling the Mystery Behind Silvering in Book Cover! 😖 Ever Seen a Book Cover Weep? The Mystery of Lamination Silvering, Solved!

🔍Introducing Bindwel’s Tech Trove – where we solve YOUR printing mysteries!

Remember that sinking feeling when a perfectly printed book cover starts to separate? It’s like your creation is shedding tears! But fear not, fellow bookworms and printing pros, because Bindwel is here to crack the case of lamination silvering.

We received this problem from a customer and reported it to the print and bind experts at Bindwel, led by Suresh Nair. Let’s delve into the investigation!

Investigate the culprits behind Silvering in book cover:

- The sneaky suspect: Is it the temperature, the film, or something more sinister?

- Clues from the scene: We’ll delve into the science behind adhesion and the impact of eco-friendly choices.

- Cracking the code: Our experts unveil solutions to keep your book covers looking flawless.

Be a printing pro and impress your clients with your problem-solving skills!

Understanding Silvering: What is it? 🤔

Silvering refers to the metallic sheen that sometimes appears on book covers, particularly those with dark backgrounds. This phenomenon occurs during the lamination process, where a thin film with adhesive properties is applied to the cover and pressed against the paper.

Types of Silvering:

- Dust spot: Dust particles on book covers, caused by dusty plant conditions, can lead to small round silvery spots when sandwiched between the film and cover material during lamination.

- Embossing

- Scoring/ Creasing

Ready to become a lamination detective?

The Silvering Suspect Line-up 🕵️♂️

They say a picture is worth a thousand words, but what if that picture is a book cover with a separating film? This wasn’t just a cosmetic issue; it was a mystery begging to be solved. As printing enthusiasts at Bindwel, we couldn’t resist the challenge!

Silvering: The unwanted guest on your book covers. But who invited it? Our investigation led us to a cast of suspects:

Temperature Troublemaker: Was the lamination machine too hot or too cold for the new, thicker film? ️The lamination machine might be running at a temperature that’s not compatible with the new, thicker film being used.

️Film Foe: Could the eco-friendly, thicker film be the culprit due to its different composition? The thicker film, chosen for sustainability reasons, might not adhere as well as its thinner counterparts. Going green is important, but it shouldn’t come at the cost of quality! The new, thicker film mandated by regulations might be causing the silvering issue.

Creasing Culprit: Did the creasing process unknowingly stretch the film, leading to future tears? The stretching of the film during the creasing process can contribute to the silvering issue.

Substrate Saboteur: The paper’s surface roughness can play a role in how well the film sticks.

Behind the Scenes: The Science of Lamination

Lamination is like a love story between paper and film, held together by the magic of adhesives. But like any relationship, it requires the right balance. We explored factors like:

- Adhesion: How well the glue bonds with the paper and film.

- Substrate: The paper’s surface texture and its impact on bonding.

- Film thickness: The effect of thicker films on heat transfer and adhesion.

Understanding the difference between thermal and wet lamination can shed light on the silvering issue:

- Thermal lamination: Utilizes heat to bond the film to the cover, offering superior quality but susceptible to silvering.

- Wet lamination: Relies on a natural curing process and is less prone to silvering but may compromise print quality.

The Smoking Gun 💥

After careful analysis, we identified the culprit: Inconsistent temperature! The thicker film required a slightly higher temperature for optimal adhesion. The eco-friendliness wasn’t the problem, but the lack of temperature adjustment was.

Justice Served! Cracking the Silvering Code ⚖️

With the culprit identified, we implemented the solution: Calibrated lamination temperatures. By adjusting the heat based on the film thickness, we ensured a strong, lasting bond, saving countless book covers from tears.

The good news? This printing mystery has solutions! Conquering silvering requires a multi-faceted approach. Here’s how to achieve flawless lamination:

- Dial in the Heat – Temperature Adjustment: Adjusting the lamination temperature based on the film thickness is key. Fine-tuning the lamination machine’s heat settings can mitigate silvering.

- Repass & Relax: Re-heating already laminated covers can sometimes fix the issue.

- Film Finesse: Opting for lesser micron lamination film reduces the risk of silvering but may not comply with government regulations and impacts recyclability.

- Crease with Care: Optimizing the creasing process to avoid film stretching is essential. A Good binding machine with ornamental and hinge creasing facility that does not break the cover is bare minimum.

- Material Selection: Choosing high-quality substrates and adhesives minimizes silvering potential.

- Process Optimization: Implementing best practices and proper workflow management enhances printing outcomes.

Embracing Innovation: Bindwel’s Role in Solving Silvering Woes

At Bindwel, we’re passionate about revolutionizing the printing industry and addressing common challenges like silvering. Our cutting-edge solutions and expert guidance empower printers to overcome obstacles and achieve exceptional results. Partner with us to elevate your printing game and unlock new possibilities in book production!

Take Action: Let’s Connect and Conquer Silvering Together!

Ready to bid farewell to silvering woes and elevate your book printing projects to new heights? Reach out to Bindwel today to explore our innovative solutions and industry-leading expertise. Together, we’ll turn printing challenges into opportunities for success!

Beyond the Silvering Saga: You’re the Hero! 💪

Now you, too, can be a lamination hero! Share this post with your fellow printing pros and help spread the knowledge. Remember, knowledge is power! By understanding the causes and solutions of silvering, you can ensure top-notch book printing every time. The perfect book deserves a cover that stays flawless.

Don’t Let Silvering Dim Your Printing Dreams—Take Charge Today!

Join us! Let’s build a community of printing pros! Share your experiences with book lamination in the comments below.

👉 Follow Bindwel on social media for more case studies and insights into our innovative binding solutions!

Stay ahead of the curve in the world of bookbinding! Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.

#bindwel #silveringissue #bindwelsolutions #printingtips #thoughtleadership #silvering #bookcover #solutions #manufacturing #perfectbinding #bookbinding #experiencematters #printindustry #bookprinting