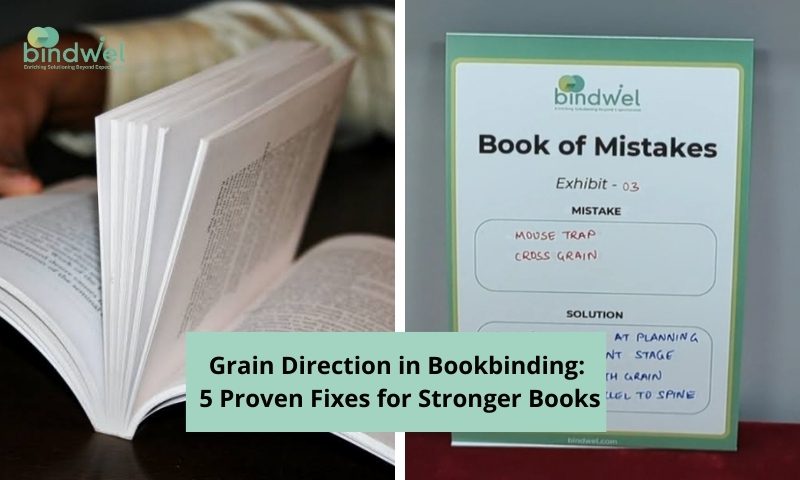

Grain Direction in Bookbinding is one of the most overlooked—and most costly—factors in book production. Ignore it, and you’ll see the same problems on repeat: stiff “mousetrap” books that snap shut, cracked hinges, warped trims, and frustrated customers.

Whether you print offset, inkjet, or toner, the wrong grain will show up on your shop floor. The good news? This mistake is 100% preventable if you enforce a few simple, pro-level practices.

The #1 Book Binding Mistake: Cross-Grain “Mousetrap” Books

Every bindery has faced this. A batch of books comes off the line looking fine—until a reader opens them. Instead of lying flat, the book resists, creaks, and snaps shut like a mousetrap. That failure kills the reader’s experience and your credibility.

So why does this happen? And how do you stop it for good?

Why It Happens

Cross-grain errors are rarely random. They creep in because of:

- Format traps: A4 landscape or A5 impositions often force cross-grain cuts.

- Mixed grain in the same job: Text stock and cover stock running in different directions.

- Cover grain ignored: Heavy covers imposed against the spine, instead of along it.

The result? A book that fights its own binding.

Symptoms to Watch For

You don’t need lab equipment to detect grain direction mistakes. The signs are visible and tactile:

- Books that snap shut when opened.

- Stiff hinges that resist or crack after a few uses.

- Trim waviness or feathered edges.

- Reader complaints about difficult handling.

If these symptoms appear, grain direction is the first thing you should check.

Quick Wins to Fix Grain Direction in Bookbinding

Here are immediate steps your floor can take:

- Enforce the golden rule: Grain must always run parallel to the spine (for both text and cover).

- Add a two-step grain gate:

- Tear-test at goods receipt.

- Grain direction stamp on every job ticket.

- Flag high-risk formats (like A4 landscape) in prepress using automated warnings.

These quick wins alone will eliminate most recurring problems.

Pro Practices for Long-Term Reliability

To go beyond quick fixes and truly bulletproof your workflow:

- Save imposition presets that preserve grain direction and avoid common traps.

- Double-score heavy covers and adjust hinge scores to match block caliper.

- Maintain a format risk map — a live record of formats prone to grain issues. Review it weekly in production meetings.

This ensures grain errors don’t just get caught — they get prevented.

What to Measure on Your Floor

Tracking these metrics ensures you know if your cross-grain problem is improving:

- % of jobs flagged for grain non-conformity during goods-receipt and prepress checks.

- Number of hinge-crack complaints logged by QC or reported by customers.

- Operator-reported cases of “stiff opening” caught during first-off inspections.

When you measure these, grain mistakes stop being invisible — they become trackable and fixable.

Field Diagnostics — If You See This → Check That

Here’s a simple diagnostic table you can keep on your floor:

- Stiff opening / book snaps shut → Check grain direction of text and cover, hinge score depth, nipping pressure.

- Cracked hinges → Verify cover grain alignment, scoring depth, and inner block grain.

- Wavy trim edges → Review knife sharpness, nipping dwell, and paper moisture.

This saves hours of guesswork when troubleshooting live jobs.

The First-Off Audit Checklist

The smartest way to stop grain mistakes is by catching them during the first-off copy. A simple audit routine can prevent hours of wasted binding and trimming.

Your first-off audit should always include:

- Grain gate test for both text and cover.

- Verify imposition preset preserves correct grain direction.

- Confirm hinge scores match the inner block’s caliper.

- Cross-check cover grain runs parallel to the spine.

This checklist takes less than two minutes but drastically reduces rework. Shops that adopt it report near-zero customer complaints about stiff or snapping books.

Why Grain Direction in Bookbinding Matters Now

Shorter runs, higher SKU counts, and faster turnarounds mean one truth: there’s no margin for error.

Every bad batch creates rework, wasted paper, and dissatisfied customers. Grain direction isn’t a small detail — it’s a profit lever. By getting it right, you deliver books that open well, last longer, and strengthen customer trust.

Bindwel’s Advisory Approach

At Bindwel, we don’t just build machines — we help printers and publishers eliminate the mistakes that erode margins.

Our advisory programs include:

- Shop-floor clinics to train teams on grain handling.

- Imposition best practices that reduce cross-grain risks.

- Continuous improvement routines with weekly metrics review.

When you control grain direction in bookbinding, you control quality — and the customer experience.

Turning the Page

Grain mistakes don’t just break books — they break trust. By applying these fixes, tracking the right metrics, and embedding grain discipline in your workflow, you ensure every book reads the way it should.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.