What if one investment could eliminate outsourcing, speed up delivery timelines, and unlock creative products your shop could never offer before?

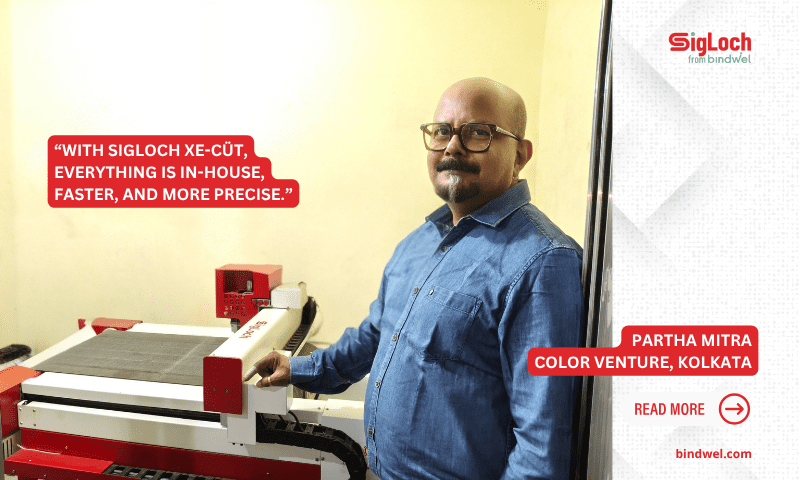

For Color Venture in Kolkata, adopting a custom sample making machine did exactly that — and reshaped their digital finishing workflow almost overnight.

A New Era of In-House Precision

At Color Venture, their goal has always been simple: deliver innovative, high-quality commercial print products for corporate brands and local businesses. Their portfolio spans diaries, calendars, catalogues, danglers, mono cartons, gift products, writing pads, and more.

But while their printing capabilities were strong, one gap kept slowing them down — finishing short-run customised jobs with precision.

Founder Partha Mitra explained it clearly:

“Previously, we used to outsource our jobs, so we didn’t have any control on the production. Now we have an end-to-end solution in-house and our quality has improved along with on-time delivery.”

The turning point?

Their decision to bring home the SigLoch XE-CÜT, Bindwel’s digital flatbed cutting system — engineered as a true custom sample making machine for modern print shops.

Faster Prototyping & Zero Outsourcing Delays

Short-run custom jobs demand speed. Clients need mockups tomorrow, not next week. For Color Venture, outsourcing created unpredictable timelines and reduced their control over the final product.

The custom sample making machine completely redefined this workflow.

How it helped:

- Rapid prototyping for mock-ups and urgent design approvals

- Ability to execute any shape with precision — no dependency on dies

- Immediate sampling for corporate jobs and premium customised products

- Dramatically faster turnaround for small-batch production

The result?

A 2–4 day turnaround on unique projects like their recent writing-pad stand gift item, which required highly precise cutting angles and tight tolerances.

According to Partha:

“The design of the stand was very unique and required precision cutting and control — which SigLoch XE-CÜT helped us achieve.”

Precision Cutting for Complex Shapes & Premium Jobs

The heart of a custom sample making machine lies in its accuracy — and this is where the XE-CÜT outperforms traditional methods.

Powered by:

- Advanced XY Robotics

- Pneumatic tool control

- ±0.1mm repeat accuracy

- Multiple tools (cutting / kiss-cutting / creasing)

…it brings offset-grade finishing to digital print workflows.

Why this custom sample making machine matters for print shops:

- No distortion on intricate shapes

- Ideal for mono cartons, rigid sleeves, danglers, and gifting concepts

- Superior consistency across short runs

- Cleaner edges and creases, enhancing perceived value

Partha highlighted this ease-of-use in his feedback:

“The machine features and bed size have enabled me to do precision work, and it takes very little space.”

And with full compatibility across paper, board, sticker sheets, magnetic sheets and more (up to 600 GSM), one machine handles an entire range of niche products.

Easy Job Switching & Profitable Short-Run Customisation

Short runs are only profitable when job changeovers are fast and workflows are smooth. The custom sample making machine makes this efficiency possible through automation-driven features.

Key advantages:

- Quick job changeovers reduce idle time

- Auto-feeding with QR Code recognition for instant job setup

- No need for highly skilled operators

- Supports multiple jobs every hour

For a print shop handling diverse daily orders, these savings compound quickly and directly improve margins.

Partha summarised it well:

“Easy job changeover lets me do multiple jobs, and I can even do box production efficiently.”

And Bindwel’s direct technical support plays a crucial role:

“The service team is very responsive and their technical skills are very good.”

Even product managers from the factory visit regularly to train the team on new applications and advanced capabilities — an advantage only a Made-in-India manufacturer can provide.

A Print Shop That Now Says ‘Yes’ to More Jobs

Thanks to their custom sample making machine, Color Venture now delivers:

- Faster approvals for corporate clients

- Precision finishing for premium products

- End-to-end in-house control

- Better reliability and consistent quality

- New capabilities in box making and gift-item fabrication

And when asked if he would recommend Bindwel, Partha’s response was immediate:

“Yes, I will definitely recommend it as it is an Indian company with a quality product and a responsible service team.”

A Finishing System Designed for the Future of Print

In a market where customisation, speed, and precision define competitive advantage, a custom sample making machine isn’t just an upgrade — it’s a growth engine.

For Color Venture, SigLoch XE-CÜT has become the tool that closes deals faster, delivers creativity without compromise, and strengthens customer relationships with every job.

Want to see the full power of digital finishing?

Meet us in person at East India Print and Pack 2025, Kolkata

Here’s what awaits you:

- Live demos of SigLoch ZEN (single-clamp binder) and XE-CÜT Pro (advanced flatbed cutter)

- Hands-on experience with fast setups and precision cutting

- Practical insights on making short-run jobs profitable

- Guidance on service, spares, and Made-in-India reliability

📍 Biswa Bangla Mela Prangan, Kolkata

🗓️ November 28–30, 2025

📌 Stall D83

Come discover how the right finishing technology can transform your business.

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production