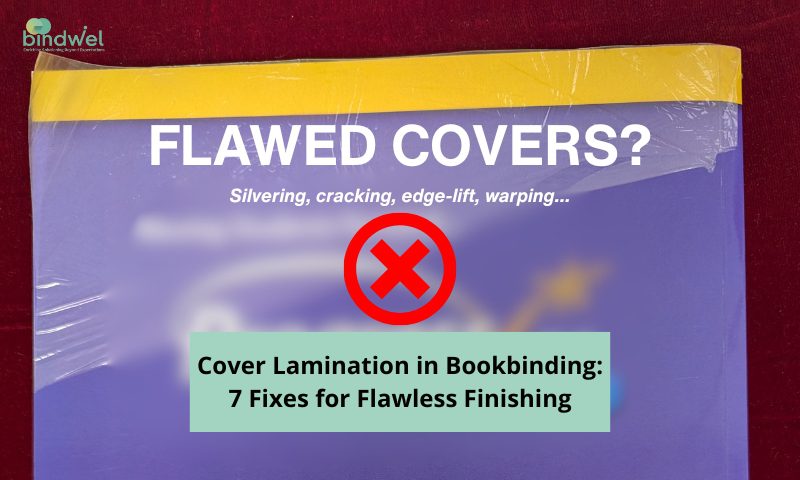

Cover Lamination in Bookbinding is the stage that decides whether a book looks premium—or gets returned. Even with perfect printing and binding, silvered laminates, cracking folds, or warped covers ruin shelf appeal.

Publishers know this better than anyone: readers judge a book first by its cover. And if lamination defects show up 24 hours after packing, they don’t just increase rework—they damage reputation.

This blog breaks down the common lamination mistakes and the proven fixes that keep covers looking flawless.

The Costly Mistake: Wrong Substrate & Lamination Settings

Most cover failures come from mismatched films or incorrect lamination parameters. The root causes are:

- Choosing the wrong lamination film for toner/digital inks.

- Using untreated films that cause silvering.

- Incorrect nip temperature or pressure causing thermal delamination.

- Too slow or too fast pass through of cover in lamination machine

- Improper hinge scores lead to cover cracking.

- Shrink-wrap tunnels set too hot, leaving covers warped or cupped.

These mistakes often pass unnoticed at dispatch—only to show up in retail conditions.

Symptoms of Lamination & Cover Defects

Here’s what printers and publishers need to watch for:

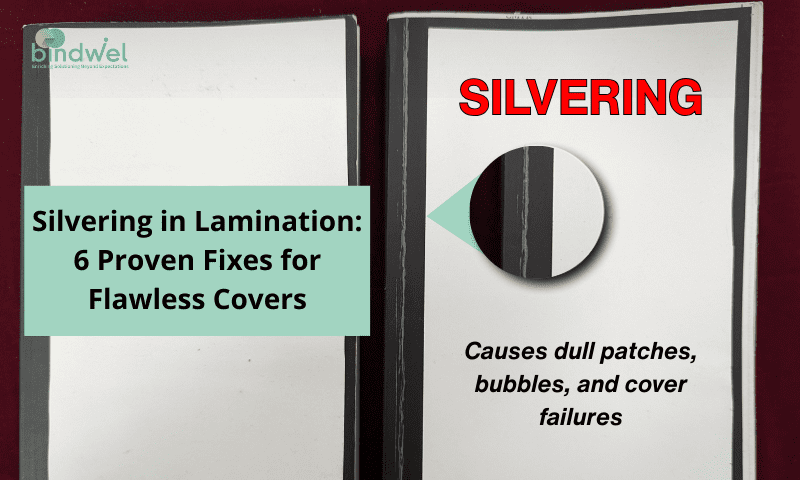

- Silvering beneath film → tiny bubbles or shiny patches under lamination.

- Edge lift after 24–48 hours → laminate peels at spine or fore-edge.

- Cracks on cover folds → visible white lines when covers bend.

- Cupped or warped covers → heat stress or moisture imbalance.

Each symptom is a signal: something’s wrong with substrate choice, scoring, thermal control, or atmospheric conditions.

Best Practices for Zero Defects: Cover Lamination in Bookbinding

FIX 1: Choose the right film for the job: toner/digital inks need corona-treated or scuff-free films.

FIX 2: Score before fold: double-score heavier covers; align scores to the true caliper of the book block.

FIX 3: Clean sheets before lamination: dust or ink residues often trigger edge lift.

FIX 4: Rest laminated sheets overnight before scoring or folding to stabilize film adhesion.

FIX 5: Develop a cover fitness test: 10× hinge folds, rub test, and 24-hour edge-lift check.

FIX 6: Map Relative Humidity (Rh %) across laminator, binder, and packing areas—moisture imbalance drives warping.

FIX 7: Introduce lamination incident logs: ensure every failure is recorded with film type, operator, and parameter settings.

Bonus: Train operators to spot silvering instantly under angled light.

These quick wins prevent most of the cover related complaints.

The Cover Lamination Audit Checklist

During first-off inspection, every team should verify:

- Film type matches ink/coverage requirements.

- Corona treatment confirmed for digital toner jobs.

- Scores are aligned to the spine and match block calipers.

- Edge-lift check after 24 hours passes.

- Shrink-wrap tunnel inlet/outlet temps calibrated & logged.

A 5-point checklist like this eliminates hidden rework.

What to Measure

If you want to stop lamination defects, start tracking these metrics:

- Silvering incidence rate by film type.

- Rework % due to lamination or cover cracking.

- Tunnel temperature stability vs. warped cover complaints.

- Edge-lift returns within 48 hours of production.

Making lamination measurable makes it manageable.

Why Cover Lamination in Bookbinding Matters Now

In the past, lamination defects were brushed off as “cosmetic.” Today, in a competitive book market, readers expect offset-level finish even on short runs. Retailers won’t stock books that curl or crack, and publishers won’t reorder from binders with recurring lamination issues.

Perfect covers aren’t optional—they are a survival requirement.

Bindwel’s Advisory Approach

Bindwel helps printers and publishers prevent lamination defects through:

- Training operators on cover scoring, lamination recipes, and film choice.

- Running shop-floor diagnostics to detect Rh % and heat imbalances.

- Providing quick-reference playbooks for troubleshooting lamination issues.

We don’t just fix machines—we fix outcomes.

The Final Touch that Sells the Book

A flawless cover isn’t just packaging. It’s the handshake between your book and its reader. If it warps, cracks, or silvers, the book is already judged.

Cover lamination in bookbinding is the final detail that elevates a product from ordinary to retail-ready.

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production