Bookbinding mistakes — two words that silently bleed away profits, trust, and reputation in the printing industry.

During the 90-minute Bindwel “Books of Mistakes” Webinar held on 9 October 2025, over 75+ participants from 8 countries joined to uncover a simple truth: rejections are the biggest hidden cost in book manufacturing.

Hosted by P. Sajith (CEO, Bindwel-Stelda Group) and Shreya Sajith (Lead, Engagement & Growth), with technical insights from Suresh Nair (CTO, Bindwel), the session transformed every printer’s perspective on what truly affects profitability. The interactive webinar featured live polls, real case studies, and a flood of questions from attendees eager to eliminate costly reworks.

Rejections: The Silent Profit Killer

In one poll, 52% of attendees identified rejections as the biggest cost in book production — even above paper (45%) and adhesives (3%).

Sajith explained it best:

“Even a 1% rejection rate of total turnover can lead to thousands of wasted books, margin loss, and penalties — often ending in customer loss.”

Every rejected shipment is not just a stack of wasted books — it’s lost credibility.

To bring this alive, Sajith shared a real-life story:

A trusted printer imported adhesive from South-East Asia for years without issues. But one cold December batch turned brittle. By summer, thousands of schoolbooks failed — the adhesive cracked under heat. A simple test across temperature zones could have prevented a massive rejection.

That’s the power of process discipline.

Why This Session Mattered

The session focused on one message — every rejection has a root cause. From planning and paper to adhesives and machines, small oversights at each stage compound into expensive reprints.

Bindwel’s team took participants through five major categories of bookbinding mistakes, demonstrating real failures and practical prevention methods.

🧱 1. Planning & Substrate Selection Mistakes

Planning errors often start long before production.

Common Mistakes:

- Wrong substrate or board selection

- Incorrect creasing depth

- Cross or mixed grain in covers and signatures

Impact:

Covers fail to open smoothly or lift from the spine, leading to usability complaints and shipment rejections.

Solution Highlights:

✅ Choose cover boards with correct grain direction

✅ Ensure proper creasing channel depth

✅ Match roller and adhesive settings

These steps might sound basic, but they define whether your book opens beautifully or fails miserably.

🎞️ 2. Lamination Failures

“When films fail, profits peel away.”

Adhesives in lamination are invisible yet critical. The team highlighted bookbinding mistakes like silvering, delamination, and wrinkling, which occur due to:

- Improper lamination temperature, speed, or pressure

- Non–corona-treated films

- Poor adhesive bonding in wet or thermal lamination

Pro Tips:

- Use corona-treated films for better adhesion.

- Monitor temperature and roller pressure regularly.

- Allow proper curing time before QC dispatch.

📊 A poll revealed that most printers face silvering and delamination more than any other lamination issue — a wake-up call for better machine calibration.

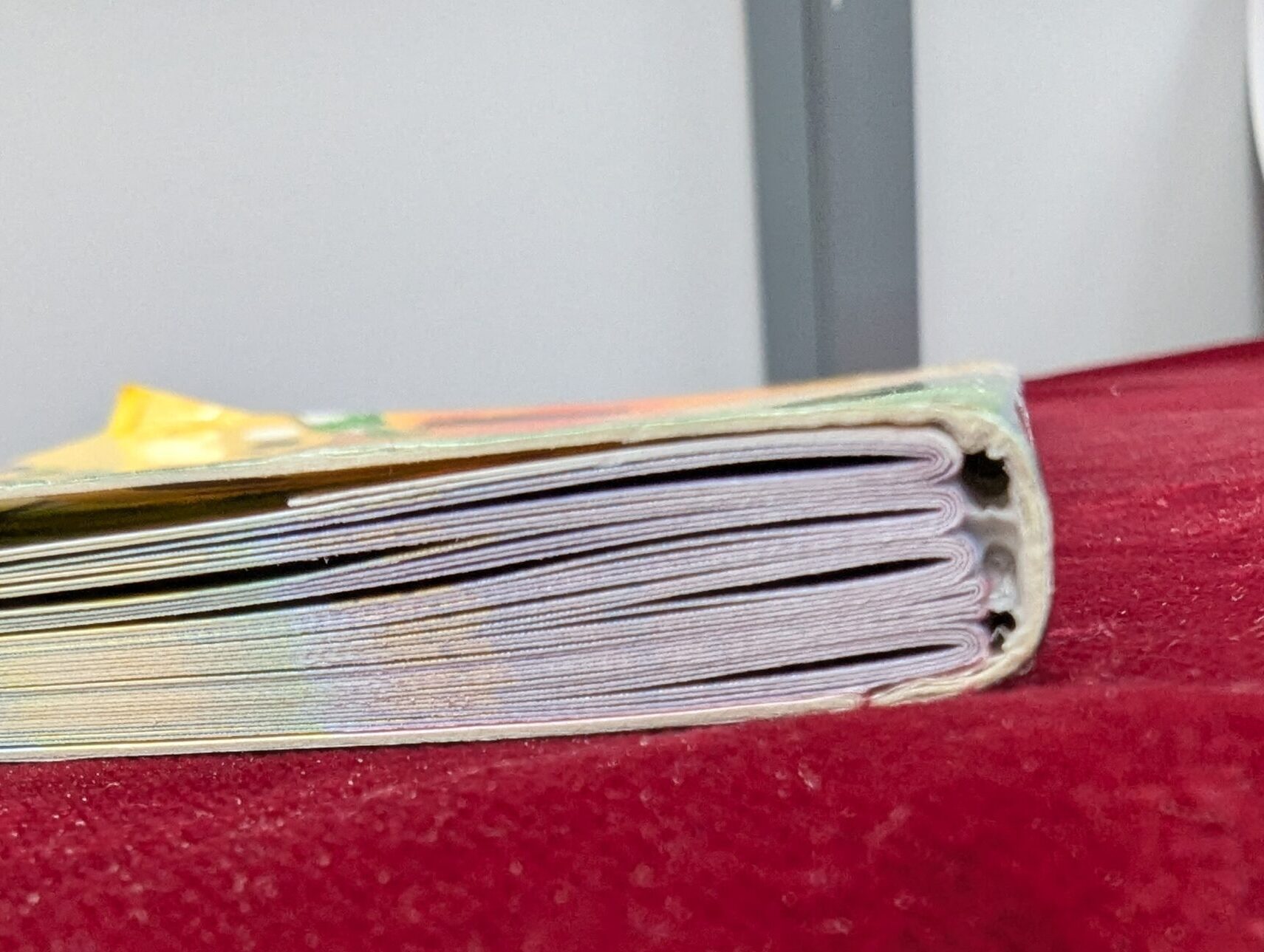

⚙️ 3. Process & Handling Errors

Process and handling errors are the invisible disruptors on the shop floor.

Typical Rejections Include:

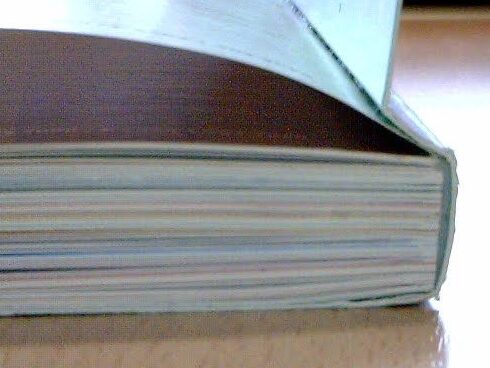

- Blowholes on the spine due to poor pressing or bundling of signatures

- Crow’s feet (extra spine folds) from improper folding without perforation

Solutions:

- Press and bundle signatures evenly, especially at the head-side.

- Add head-side perforation to relieve tension.

- Train folding operators on correct alignment and handling.

Suresh Nair reminded participants, “Handling matters as much as machines.”

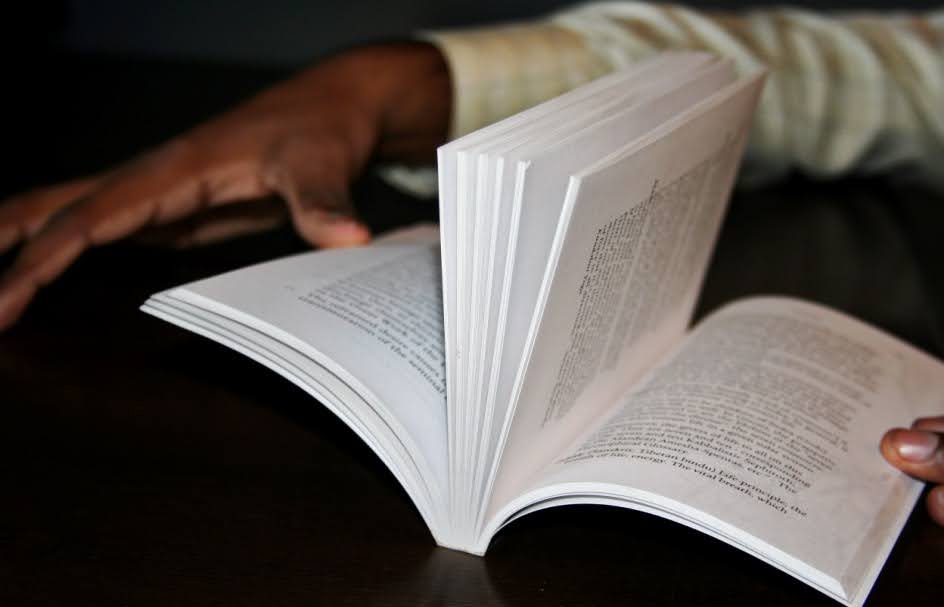

🌦️ 4. Paper & Environment Issues

Paper is a living material — it reacts to the environment.

Common Problems:

- Mouse trap effect – books snapping shut due to cross grain

- Web growth – uneven trimming and wrinkles from mixed grain

- Honeycombing – moisture absorption during storage

Preventive Actions:

- Maintain 55% humidity and 4.5–5% paper moisture

- Store and acclimatize paper before printing

- Avoid mixing paper grain lots

Bindwel emphasized that moisture and grain direction together cause over 60% of visible book defects.

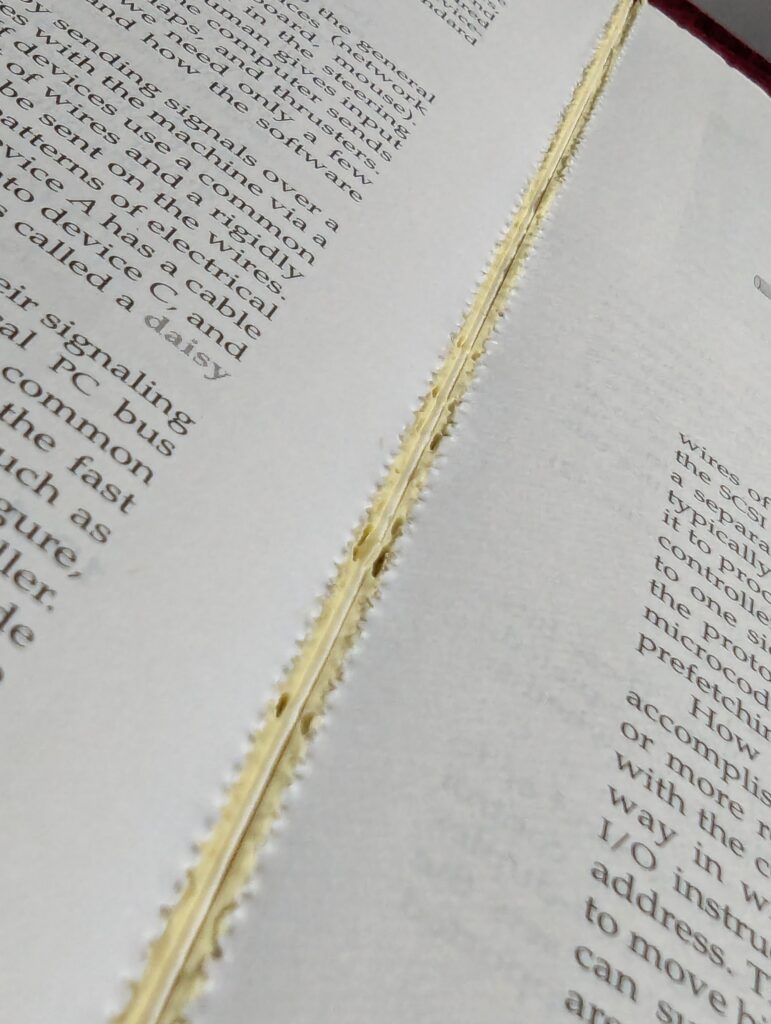

🧰 5. Machine & Maintenance Problems

A well-maintained machine is your insurance policy against rejections.

Frequent Issues:

- Poor spine prep – blunt milling cutters or shallow notching

- Glue strings – wrong roller settings or low temperature

- Unclean glue pots and neglected maintenance

Bindwel’s Advice:

- Schedule preventive maintenance, not reactive fixes.

- Check adhesive temperature daily.

- Replace blunt tools before failure occurs.

A live poll revealed that only a small percentage of printers always follow preventive maintenance — reinforcing the need for operator awareness.

From Rejections to Process Excellence: The BindRight Program

The webinar concluded with an introduction to BindRight, Bindwel’s signature diagnostic and training initiative.

BindRight = Diagnostic + Preventive + Deep Learning Program

It offers:

- Adhesive audits

- Machine calibration

- Operator training

- Hands-on failure analysis

Printers were even invited to send their failed books for evaluation.

“Got a rejected or failed book? Send it to us — our experts will identify the issue and guide you toward a fix.”

BindRight transforms rejections into learnings — turning every mistake into process excellence.

Key Takeaways from the Webinar

- Rejection is the real cost killer — not materials.

- Most binding problems start in planning, not production.

- Grain direction is non-negotiable — it’s the backbone of quality.

- Moisture is the invisible enemy — control the environment.

- Train. Retrain. Repeat. — machines can’t fix what people don’t understand.

A Movement for Smarter Bookbinding

With lots of valuable interactions, the Books of Mistakes Webinar wasn’t just an event — it was a movement to build a smarter, more profitable, and rejection-free printing ecosystem.

Bindwel’s mission is simple:

👉 Help printers prevent bookbinding mistakes before they happen.

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube to stay updated on more upcoming masterclasses, open houses, and insights that make bookbinding smarter and stronger.