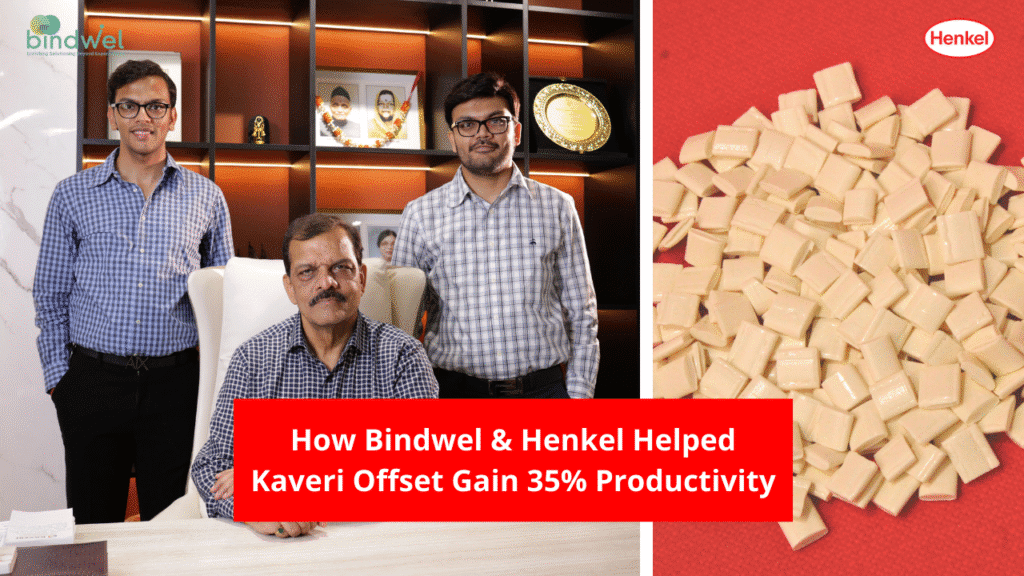

Bookbinding Adhesive Solutions often get treated as a consumable—yet they directly affect uptime, per-book cost and finished quality. Kaveri Offset, a 39-year family binder producing ~100,000 books a year, independently compared adhesives on their lines and reported clear shop-floor improvements after switching to Henkel. Below is their experience, the shop-floor KPIs they tracked, the Henkel grades they used, and how other binderies can judge similar adhesives in real production.

Who Kaveri Offset is

Kaveri Offset is a 39-year family-run printer-binder producing roughly 100,000 books a year for publishers and government projects. They purchased Henkel adhesives (4525) for in-house benchmarking and ran comparisons across two machines to measure real differences in melt time, mileage and downtime.

What Kaveri measured

All observations below are Kaveri Offset’s own findings over the trial and subsequent runs:

- Melt time: Henkel melted in 30–45 minutes vs 40–50 minutes for the previous adhesives — meaning quicker machine readiness and fewer warm-up issues.

- Glue tank life / maintenance: Glue-tank cleanings stretched from roughly ~1 year to ~3–3.5 years after switching to Henkel — less tank char and fewer scheduled cleanouts.

- Productivity uplift: Kaveri recorded approximately ~35% higher throughput on matched jobs after the transition.

- Mileage (books per kg): Operators logged better mileage with Henkel — more finished books per kilogram of adhesive.

- Uptime & breakdowns: Machine counters and operator logs showed fewer unscheduled stops and improved line uptime.

- Quality & consistency: Fewer book-open issues and more consistent spines even under high ambient temperatures.

These outcomes came from Kaveri’s machine counters, adhesive-usage logs and maintenance records — real shop-floor evidence rather than isolated claims.

7 concrete wins Kaveri reported with Henkel Bookbinding Adhesive Solutions

- Faster warm-up / melt times — quicker start of shift and reduced start-up defects.

- Longer glue-tank maintenance cycles — less frequent cleanouts and lower maintenance labour.

- ~35% productivity uplift — consistent feed and set behavior reduced stops and increased throughput.

- Better books/kg (mileage) — material efficiency improved, lowering glue cost per finished book.

- Thermal stability in heat — predictable viscosity and set even in high ambient conditions.

- Stronger client confidence — Kaveri reports clients feel reassured when told Henkel is used.

- Operator peace of mind — fewer emergency interventions, more predictable shifts.

Why these Bookbinding Adhesive Solutions worked

Kaveri’s improvements are tied to three practical factors:

- Melt & conditioning behaviour: Faster and stable melt reduces degraded polymer and char in the tank.

- Viscosity stability & transfer: Predictable melt viscosity improves transfer to the spine and reduces waste.

- Application fit: Correct open/set time and compatibility with Kaveri’s paper mix ensured strong fibre bonding rather than surface tack.

In short: improved melt time, viscosity control and adhesive transfer created measurable uptime and mileage improvements for Kaveri.

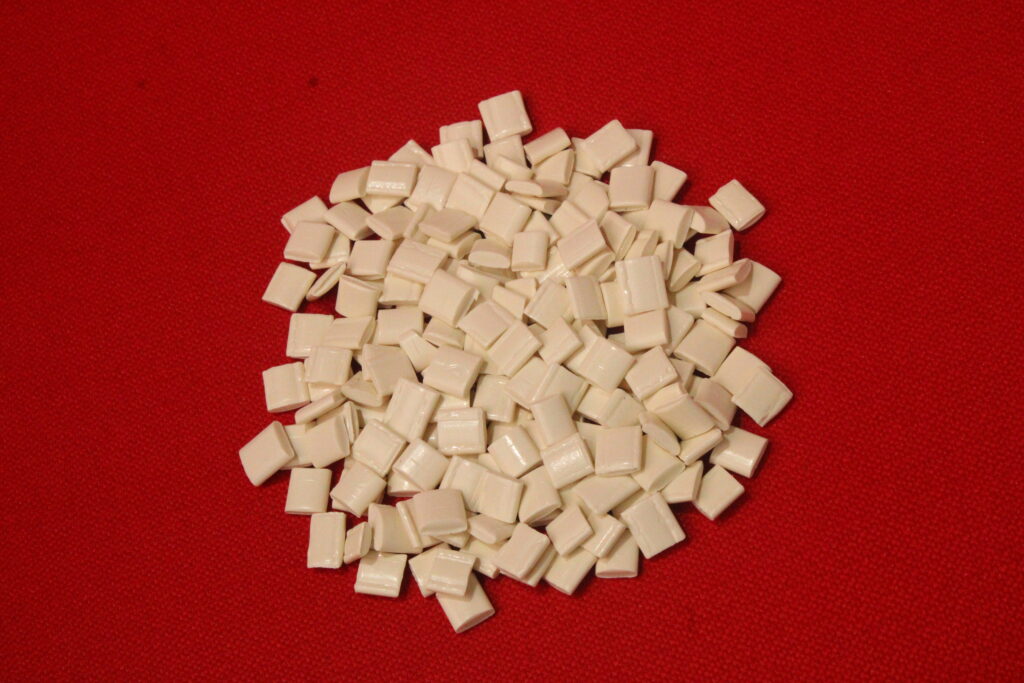

Henkel grades used at Kaveri

Henkel 4525 — A higher-viscosity grade suited to thicker or stitched books where a firmer spine finish is needed. Works well on Maplitho and similar stocks with stable setting characteristics.

(For full datasheets, recommended temperature curves and handling charts, contact Bindwel now!)

What this meant commercially for Kaveri Offset

Kaveri told us their clients reacted positively when they disclosed the switch to Henkel — approvals were faster and some large buyers showed increased confidence in delivery quality. For Kaveri, the adhesive choice became a visible quality signal in commercial conversations.

How binderies should evaluate Bookbinding Adhesive Solutions (A practical checklist)

If you’re comparing adhesives in production, Kaveri’s practical approach is a good template:

- Run side-by-side comparisons on identical jobs and record machine counters.

- Track melt time from cold start to steady viscosity.

- Log books/kg (mileage) over representative runs.

- Record glue tank condition and cleanout frequency.

- Measure uptime & unplanned stops via counters or logs.

- Check finished-book behavior (spine set, book-open tests) under typical ambient temperatures.

This focuses your evaluation on yield, uptime and finished quality — the three levers that affect margin.

Your Next Move (how to access Henkel Bookbinding Adhesive Solutions)

If you want to replicate Kaveri’s checks, Bindwel supplies genuine Henkel Bookbinding adhesive solutions in India. Contact Bindwel today to obtain official Henkel grades, technical data sheets and recommended temperature curves.

For machines, Bindwel continues to design and manufacture bindery equipment that supports consistent adhesive application and controlled set—so your process and equipment can work together for predictable results.

Contact Bindwel Technologies for grade information and technical data sheets, and follow Bindwel for more shop-floor insights and case studies.

Stay ahead of the curve in the world of bookbinding!

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.