Unraveling Printing Mysteries with Bookhound of Bindwel! 🔎

Dive into the depths of printing puzzles as we decode complex challenges and reveal industry-leading solutions! Join us on this detective journey to keep your pages perfectly pristine.

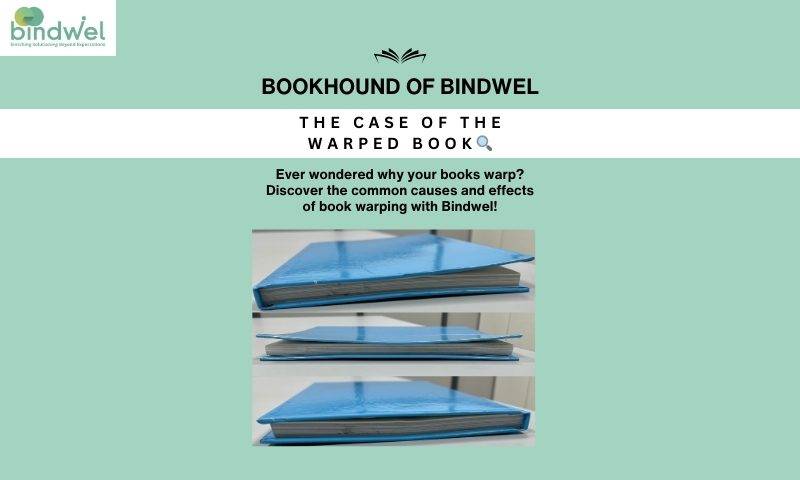

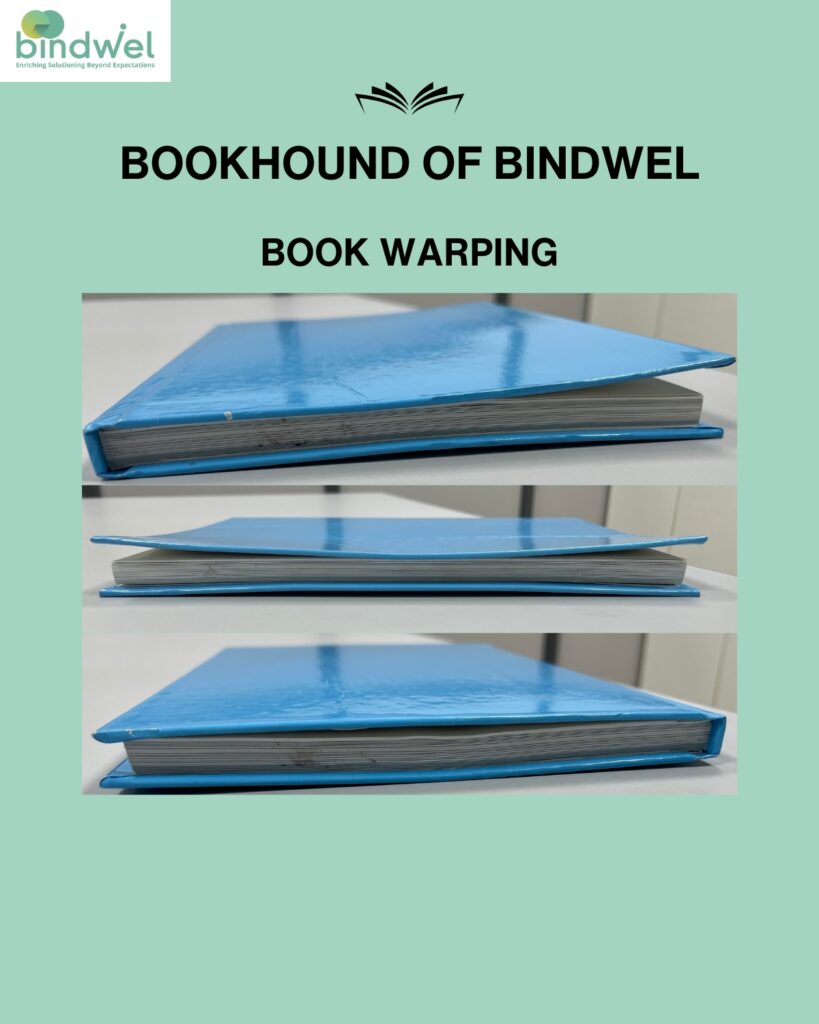

The Case of the Warped Book: A Printing Detective Story

Have you ever received a book that looked perfect at first, only to find it mysteriously warped a few days later? This isn’t a case of a haunted library – it’s a common printing mystery called book warping. But fear not, fellow book lovers and printing professionals, because Bindwel is here to crack the code and keep your books looking sharp! At Bindwel, we’re on a mission to uncover the secrets behind book warping and provide you with actionable solutions to keep your books pristine.

The Warping Woe: A Detective’s Introduction

Just like a detective examining a crime scene, we need to understand the warping phenomenon. Book warping refers to the distortion of a hard cover book, where paperboard or the covers bend, curl, or buckle. It occurs when the cover lifts away from the open side of the book. This can be seen along the spine or bulges outward, disrupting the book’s aesthetics and durability. This not only affects the book’s aesthetics but can also hinder readability and cause damage over time.

Unveiling the Culprits: What Causes Book Warping?

Our investigation reveals several suspects in the case of the warped book:

- Moisture Mischief: The culprit most often behind warping is moisture imbalance. Dispersion adhesives (Water-based) used for binding can release moisture, which the book board absorbs unevenly, causing warping. Uneven distribution of moisture during the binding process or fluctuations in humidity levels post-production can cause paper fibers/ board to expand or contract unevenly, leading to warping.

- Material Compatibility: Using incompatible materials for the cover, pages, or adhesive can lead to warping as these components interact and age differently.

- Uneven Glue Application: Inconsistent application of adhesive during casing-in (attaching the cover) can also lead to uneven warping.

- Board Blunder: The quality and grain direction of the board itself play a role. Ideally, the grain should run parallel to the spine to minimize warping.

- Temperature Trouble: Extreme heat or cold during storage can cause paper fibers to contract or expand unevenly, contributing to warping.

- Acidic Content: Recycled paper or board with high acidity levels can become brittle over time, increasing the likelihood of warping and deterioration.

Introducing the Endsheet and Casing-In Process:

Before diving deeper, let’s meet two key players in the bookbinding process:

- Endsheets: These are blank pieces of paper attached to the first and last pages of a book block, providing strength to the hinge and holding the book block together.

- Casing-In: This is the process of attaching the cover (made during case-making) to the book block using glue.

Endsheets and Casing-In: Potential Warping Culprits

Improper glue application during casing-in can contribute to warping. The glue used often has a higher water content compared to glues used in case-making. If this moisture isn’t evenly distributed or properly dried, it can cause the book board to warp.

Tunneling: The Inward Warp

We’ve discussed warping, the outward bending of the cover. But there’s another suspect: tunneling. Tunneling occurs when the cover bends inwards, creating a tunnel-like shape. While both warping and tunneling are caused by moisture imbalance, the location of the bend helps identify the source.

Identifying the Moisture Source: A Visual Clue

By examining the location of the warping, you can get clues about the moisture source:

- Warping on the Open Side (Where Pages Meet Cover): This suggests moisture from the casing-in process, likely due to uneven glue application or insufficient drying.

- Warping on the Closed Side (Spine Area): This points towards the case-making process. The glue used here might have a higher moisture content that wasn’t properly managed.

Grain Direction and Moisture: A Warping Recipe for Disaster

Grain direction refers to the natural fiber direction within the board material. When the grain runs perpendicular to the spine, it allows moisture to travel more easily, leading to more pronounced warping. Ideally, the board should have the grain running parallel to the spine for optimal stability.

Case-Making vs. Casing-In: Understanding the Glue Game

- Case-Making: This process creates the empty cover using cardboard and various materials. Glues used here, like jelly glue or animal glue, typically have a lower water content. Utilizing specialized machines, the case—a cover with boards is formed using adhesives that can affect moisture content. The type and application of adhesives here set the foundation for potential warping issues.

- Casing-In: This step attaches the pre-made cover to the book block. Water-based adhesives with a higher water content are commonly used for this process. The higher water content ensures strong adhesion, but if not managed properly, it can lead to warping. This process involves careful handling to prevent uneven moisture distribution that leads to warping and tunneling.

Effects of Book Warping

The effects of book warping extend beyond aesthetics:

- Aesthetics: Warped pages and covers diminish the overall look and feel of the book, impacting its visual appeal.

- Durability: Severely warped pages may crack or tear, compromising the book’s structural integrity and readability.

- Reader Experience: Warping can make it difficult to open and read the book comfortably, affecting user experience.

Cracking the Case: Solutions to Prevent Book Warping

With the suspects identified, here’s how to prevent book warping and ensure pristine book quality. At Bindwel, we emphasize proactive measures to prevent and mitigate book warping:

- Adhesive Selection: Choosing the right adhesive based on board compatibility is crucial. Conducting adhesive tests ensures optimal performance and minimizes the risk of warping. Testing before full production is essential.

- Moisture Management: Using high-solid content water-based adhesives reduces moisture release during binding, helping maintain paper integrity.

- Grain Direction Matters: Aligning the grain direction of the board parallel to the spine reduces the risk of warping, but perpendicular to the spine (cross grain) will lift the bend or curl the corners of the open side.

- Climate Control: Maintaining stable temperature and humidity levels in production and storage environments prevents moisture-related warping.

- Quality Control is Key: Using high-quality materials throughout the post press process minimizes warping risks. Implementing best practices in board preparation and binding techniques ensures consistency and durability in book production.

Bindwel’s Role in Combatting Book Warping

As industry leaders in printing solutions, Bindwel is committed to empowering printers with innovative technologies and expert guidance. Our comprehensive approach addresses common challenges like book warping, ensuring your printing projects achieve exceptional quality and durability.

Bindwel: Your Partner in Flawless Bookbinding

At Bindwel, we’re passionate about helping printers achieve exceptional results. We offer a range of high-quality bookbinding materials, including adhesives specifically formulated to prevent warping.

Ready to Solve the Warping Mystery?

Don’t let warped books become a part of your printing story. Contact Bindwel today to discuss your bookbinding needs and explore our solutions for flawless, long-lasting books.

Together, we can keep your books looking their best, from the very first page to the last!

👉 Follow Bindwel on social media 📱 and stay updated with the latest advancements as we approach Drupa 2024.

Stay ahead of the curve in the world of bookbinding! Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.

#bindwel #bookbinding #binding #perfectbinding #bookpublishing #books #energy #bookbindingmachines #bookwarping