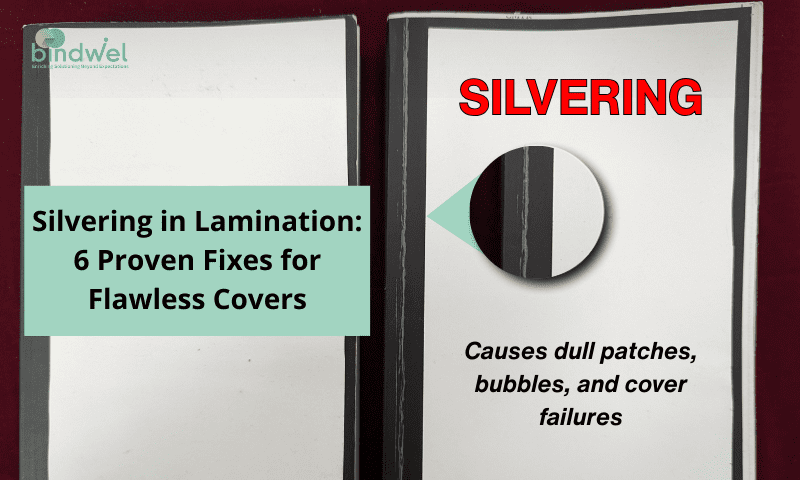

Silvering in Lamination is one of the most frustrating cover defects because it often appears after the job looks finished. A book may leave the shop looking fine, only for silver patches, bubbles, or dull areas to show up a day later.

This isn’t a printing issue. It’s a lamination and process control issue. And it affects wet (cold glue), thermal, and dry lamination workflows.

This blog explains where silvering happens, why it happens, and what actually works on the shop floor to prevent it—without theory or guesswork.

Where Silvering in Lamination Occurs

Silvering in Lamination typically shows up during or after these stages:

- Wet lamination (cold glue): When adhesive fails to bond uniformly with the printed sheet

- Thermal lamination: When film, heat, or pressure is not suited to the inked surface

- Dry lamination: When the film’s surface energy is too low to allow the adhesive to “wet” the surface, causing repulsion

- Cover grain direction: When cross-grain covers prevent proper film contact, especially near folds and spines

Understanding which stage your silvering originates from is critical. Treating all silvering the same leads to repeated failures.

Why Silvering In Lamination Happens — The Real Root Causes

Wet Lamination (Cold Glue) Issues

Silvering in wet lamination usually comes from poor adhesive bonding rather than the film itself. Common causes include:

- Incompatibility: The adhesive is not suited for coated or heavily inked surfaces.

- Application Errors: Uneven glue spread or insufficient pressure at the nip rollers prevents a uniform bond.

- Micro-pockets: When the liquid glue fails to fully “wet” the sheet, trapped air pockets appear later as silvering.

Thermal Lamination Issues

In thermal lamination, silvering is almost always linked to film suitability or heat application.

Typical reasons:

- Surface Treatment: Using film that hasn’t been specifically treated for digital toners or ink-heavy surfaces.

- Temperature Sensitivity: If the temperature is too low, the bond is weak; if it is too high, it causes surface skinning.

- Heat Reversibility: Because thermal lamination uses heat-activated hot-melt adhesives like EVA, the film can actually de-laminate if the book is exposed to heat again later

- Uneven Film Contact: Incorrect pressure or film tension, preventing uniform contact

Silvering here is rarely random—it usually repeats on the same stocks or jobs.

Dry Lamination Issues

Professional technical standards identify dry lamination as the best method for achieving high-quality results.

In this process, a liquid adhesive (chemical or water-based) is applied to the film and passed through a heating chamber to dry before it is bonded to the substrate. This creates a robust chemical bond with superior heat resistance compared to thermal methods.

However, silvering occurs if Surface Energy is neglected:

- The “Lotus Effect”: If the film’s surface energy is less than 38 dyne/cm, the adhesive will repel and form tiny beads—like water on a lotus leaf—rather than coating the surface evenly.

- Dyne Decay: Surface energy is volatile and can drop significantly within 24 hours of storage.

The Fix: The most effective way to eliminate silvering in dry lamination is using in-line Corona treatment, which uses high-voltage sparks to molecules on the film surface, increasing its energy (ideally to 40–42 dyne) to ensure perfect “wetting”

Cover grain direction problems

A significant misconception is that grain direction affects the film’s ability to make contact with the cover during the initial lamination process; in reality, grain direction does not affect the initial contact. Instead, it contributes to silvering only during creasing and folding.

When cover grain runs perpendicular to the spine:

- Structural Breakage: The stiff fibres of a cross-grain cover break unevenly at the hinge.

- The “Rubber Band” Effect: Because the film was stretched during creasing, it tends to “bounce back” to its original shape.

- Bond Failure: This tension causes the film to lift away from the unevenly broken paper surface, creating visible silver streaks and “shining” areas near the spine and folds.

How to Spot Silvering In Lamination Early

Watch for these early warning signs:

- Tiny shiny dots or cloudy patches under the laminate

- Silver streaks close to hinge scores or spine areas

- Laminate that looks fine initially but dulls after 24 hours

- Repeated failures on the same paper or cover board

A quick angled-light inspection right after lamination often reveals silvering before the job moves ahead.

Five Practical Fixes to Stop Silvering in Lamination

These are field-tested corrections, not theoretical adjustments.

1. Use films meant for toner and heavy ink coverage

Not all lamination films behave the same. For toner or high-coverage digital prints:

- Use films specifically recommended for such surfaces

- Corona-treated films help improve bonding consistency

If silvering appears only on digitally printed covers, film selection should be your first check.

2. Apply heat and pressure evenly—not aggressively

Silvering often increases when operators try to “fix” bonding by over-heating.

Instead:

- Use just enough heat to activate bonding

- Ensure pressure is uniform across the sheet

- Allow proper cooling before stacking

Excess heat can trap air and create long-term adhesion issues.

3. Improve wet lamination bonding at the nip

For cold glue lamination:

- Confirm adhesive suits coated or ink-heavy sheets

- Ensure glue spread is even across the sheet

- Adjust speed and pressure so adhesive has enough contact time

If silvering appears only after drying, adhesive wetting is the likely issue.

4. Maintain Surface Energy Between 38 to 42 Dyne

For a flawless bond, the film surface energy should ideally be between 40 and 42 dyne. Because surface treatment can decay within 24 hours of storage, the most reliable fix is using in-line Corona treatment.

This process uses high-voltage sparks to molecules on the film surface, increasing its energy and ensuring the adhesive “wets” perfectly.

5. Respect cover grain direction—especially at the spine

Always check:

- Cover grain parallel to the spine

- Grain alignment before lamination, not after

Cross-grain covers often laminate poorly even if everything else is correct. This is non-negotiable.

6. Train operators to catch silvering in lamination immediately

Silvering is easiest to fix when caught early.

Train operators to:

- Inspect under angled light

- Stop and isolate affected sheets

- Record film type, temperature, pressure, and stock

Documentation prevents repeat mistakes.

Summary of Lamination Methods

| Aspect | Wet Lamination | Dry / Thermal Lamination |

| Bond Strength | Highest (permeates fibres) | Medium–High |

| Silvering Risk | High if drying is uneven | Low if dyne levels are b/w 38 – 42 |

| Speed | Slower (limited by curing) | Very Fast (instant bond) |

| Best For | High-volume, heavy covers | Short runs, specialty finishes |

A Simple Diagnostic Flow That Actually Works

When silvering appears, check in this order:

- Film type and surface treatment

- Lamination temperature and pressure

- Sheet cleanliness and ink coverage

- Cover grain direction

- Adhesive suitability (for wet lamination)

Change one variable at a time. Random tweaks waste time and paper.

What You Should Be Measuring

To prevent silvering long-term, track:

- Silvering complaints by film type

- Rework percentage linked to lamination

- Repeat failures on specific stocks

- Time taken to detect and correct silvering

Once measured, silvering becomes predictable—and preventable.

Bindwel’s Shop-Floor Approach

Bindwel helps printers and publishers reduce silvering in lamination by:

- Reviewing film and adhesive compatibility

- Training teams to recognise early failure signs

- Helping standardise lamination settings for repeat jobs

The focus is not on equipment alone—but on consistent outcomes.

Why Silvering in Lamination Deserves Serious Attention

Silvering may look cosmetic, but it directly affects:

- Shelf appeal

- Reader perception

- Publisher confidence

In today’s market, covers must look consistent across every copy. A single silvered batch can undo weeks of good work.

| Feature | Analysis based on Sources |

| Dyne Threshold | Minimum 38 dyne; ideal at 40–42 dyne. |

| Best Method | Dry Lamination due to chemical bonding and handling tough substrates. |

| Grain Direction Myth | Corrected: affects silvering after cover creasing, not during initial contact. |

| Visual Indicators of Silvering | Film lift, reflective patches, and dulling after ~24 hours. |

| Technical Fix | In-line Corona treatment to increase surface energy |

The Finish That Defines the Book

Silvering in Lamination is not inevitable. It is the result of small, correctable gaps in process discipline.

Choose the right film. Apply controlled heat or adhesive. Respect grain direction. Train operators to spot issues early.

Do this consistently, and your covers will stop failing silently.

Stay ahead of the curve in the world of bookbinding!

👉 Follow Bindwel for more inspiration and insights on Facebook, LinkedIn, Twitter, Instagram and YouTube for the latest industry updates, innovative solutions, and expert tips to optimize your production.