Advanced Perfect Binder: The Future of Bookbinding Excellence

The world of bookbinding is evolving, and at the heart of this transformation is the Advanced Perfect Binder SigLoch Ultra CF – PUR. Designed to cater to modern printing needs, this innovative machine is the ultimate solution for short-run offset and digital book production, offering unmatched precision and automation.

As the machine continues its development journey, its potential to address pressing challenges in the bookbinding industry has already begun to generate buzz. Let’s explore how this cutting-edge technology is set to change the game.

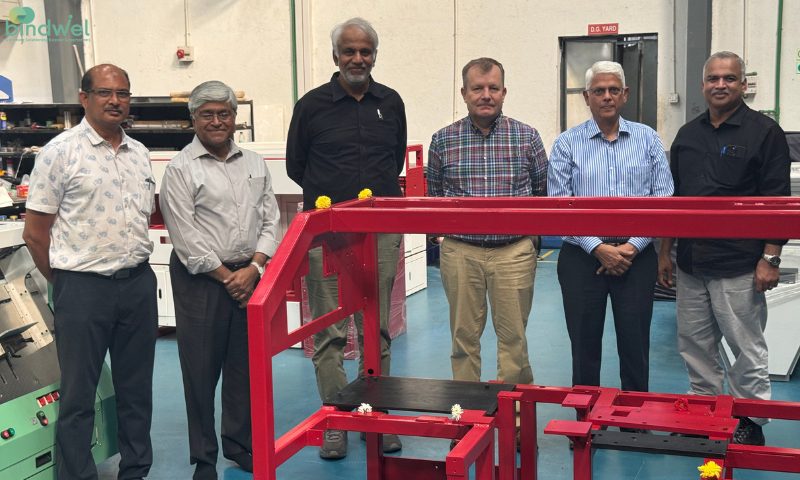

A Memorable Launch Ceremony 🎉

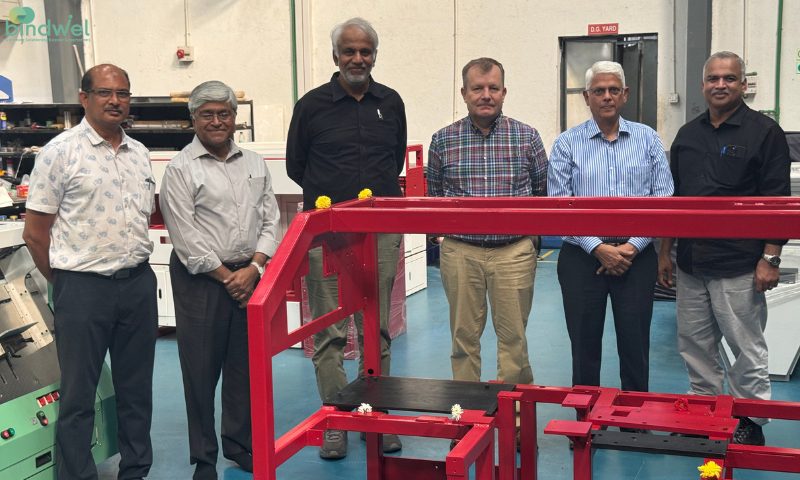

The unveiling of the SigLoch Ultra CF – PUR was nothing short of spectacular. In true tradition, the event began with an auspicious puja ceremony, symbolizing prosperity and success. The highlight of the day was the ceremonial screwing of plates onto the machine chassis by our leadership team, marking months of dedication and collaboration.

Speaking on the occasion, Mr. Sajith Pallippuram (CEO) said, “The SigLoch Ultra CF – PUR represents a bold step forward in the evolution of bookbinding. While we continue to build and refine this project, its potential to transform short-run production is unmatched.”

The Current Bookbinding Landscape 📊

The bookbinding industry is experiencing a shift, driven by technological advancements and the need for cost-effective, high-quality production. Here’s what the market looks like today:

- Demand for Short-Run Production: Publishers are focusing on personalized and limited editions to meet niche audience needs.

- Challenges with Coated Substrates: Modern books often include coated or varnished pages, which traditional binding methods struggle to handle effectively.

- Need for Automation: Efficiency gaps caused by manual setups are increasing operational costs.

These challenges highlight the pressing need for solutions like the Advanced Perfect Binder, which combines versatility, precision, and automation to address these issues head-on.

Key Pain Points Solved by the Advanced Perfect Binder 🤔

Printers and bookbinders face several recurring challenges that the SigLoch Ultra CF – PUR is specifically designed to tackle:

- 1. Handling Complex Materials

- Many machines fail to bind coated or varnished pages without additional costly steps like thread-sewing.

- The Advanced Perfect Binder eliminates this need by offering a binding process that maintains strength and durability across various substrates.

- 2. Reducing Setup Time

- Manual setup processes increase production times, especially during frequent job changeovers.

- With features like pneumatic clamping and optional book thickness measurement, this binder automates setup for faster, more efficient workflows.

- 3. Improving Binding Consistency

- Variability in book thickness and materials often leads to inconsistent results.

- The machine’s advanced nipping system and precision spine preparation tools ensure uniform, professional bindings every time.

- 4. Enhancing Operator Safety

- Traditional binding machines often compromise operator safety.

- The SigLoch Ultra CF – PUR includes a safety light barrier to protect operators, making it a reliable addition to any production floor.

Revolutionary Features of the Advanced Perfect Binder 🛠️

What makes the Advanced Perfect Binder stand out from the crowd? Here are its core features:

- PUR Spine Gluing System: Equipped with a 2KG pre-melter and slot coater for automated adjustments based on book thickness.

- Combination Spine Preparation Tool: A milling, notching, and brushing tool ensures impeccable spine preparation.

- Smart-HMI Control System: Simplifies machine operation and improves efficiency through real-time production data.

- Vertical Stack Delivery: Protects the spine and ensures high-quality finished products.

- Quick Job Changeover: Handles multiple book sizes and thicknesses effortlessly.

The Benefits of Choosing the Advanced Perfect Binder 🎯

By addressing market challenges, the Advanced Perfect Binder offers transformative benefits:

- Enhanced Productivity: Automation reduces manual intervention, allowing operators to focus on other tasks.

- Cost Efficiency: Eliminates the need for expensive processes like thread-sewing, cutting down production costs.

- Flexibility: Perfect for short-run, on-demand production, handling diverse bookbinding requirements with ease.

- Improved Quality: Consistency in binding ensures professional results, enhancing customer satisfaction.

Leadership Driving the Vision 🌟

The development of the SigLoch Ultra CF – PUR is led by a team of visionary leaders, each contributing to its success:

- Mr. Sajith Pallippuram (CEO): The driving force behind the project, focusing on innovation and market relevance.

- Mr. Kai Buentemeyer (Director, Germany): Bringing global expertise and technical precision.

- Mr. Suprotik Das (Director): Ensuring seamless project execution.

- Mr. Suresh (CTO): Innovating the machine’s technological framework.

- Mr. Arvind (Director): Strategizing operations and ensuring the highest standards of quality.

- Mr. Vishwa Prasad (Director): Driving advancements in manufacturing processes.

Their combined efforts are shaping this machine into a revolutionary tool for the bookbinding industry.

Why the SigLoch Ultra is a Game-Changer 🚀

The SigLoch Ultra CF – PUR is more than just a machine—it’s a comprehensive solution for modern bookbinding challenges. Here’s why it’s worth anticipating:

- Adaptability: Handles diverse substrates and book sizes, making it perfect for custom and niche projects.

- Precision Engineering: From gluing to nipping, every process is designed for impeccable results.

- Future-Ready Design: Built with features that cater to the evolving needs of printers and publishers.

Be Part of the Bookbinding Revolution

The SigLoch Ultra CF – PUR is a work in progress, but its innovative features and potential are already creating excitement in the industry. As we continue developing this advanced perfect binder, we’re committed to keeping you updated every step of the way.

Stay connected to follow the journey of the SigLoch Ultra CF – PUR as we bring its vision to life. We’ll share behind-the-scenes glimpses, technical updates, and insights into how this machine is set to redefine bookbinding standards.👉

Follow us on our social media channels to stay informed about milestones, innovations, and the progress of this revolutionary project.

Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for the more updates!