For publishers managing short-run educational titles, binding is not a cosmetic step.

It decides turnaround time, wastage, and whether a book reaches classrooms on schedule.

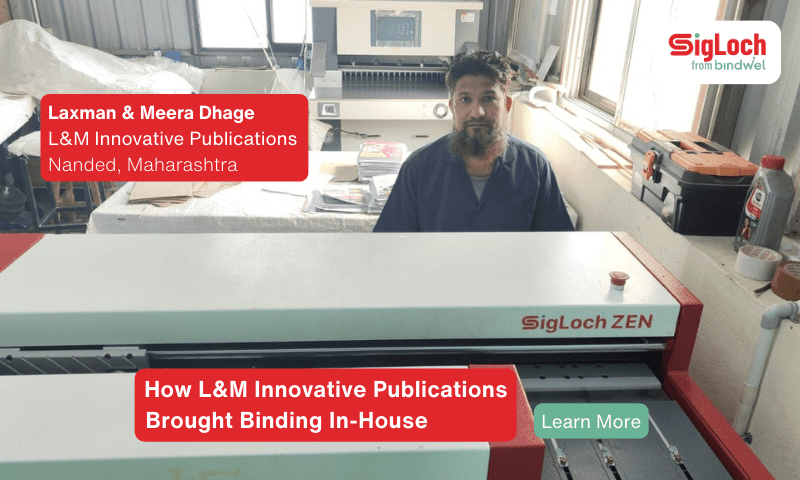

At L&M Innovative Publications, the decision to install SigLoch ZEN a digital perfect binding machine was driven by a simple operational question: Should binding remain a dependency-or become a controlled process?

📘 A Publisher Focused on Educational Consistency

Founded by Laxman and Meera Dhage, L&M Innovative Publications serves educational institutions across Maharashtra.

Their portfolio includes:

- ITI textbooks for government and private institutions

- Educational charts and instructional material

- Publications supplied through bookshops and state departments

The company operates from a 1,500-sq-ft facility in Nanded, spread across two floors.

It runs two shifts daily with a team of eight, covering both production and administration.

The scale is modest-but expectations from institutions are not.

⚠️ When Outsourced Binding Becomes a Bottleneck

Before investing in a digital perfect binding machine, L&M outsourced binding to Hyderabad.

Over time, this introduced structural issues:

- High logistics costs

- Delivery delays outside their control

- ~10% binding-related wastage

- Limited ability to commit to tighter schedules

For short-run, on-demand educational titles, these inefficiencies compounded quickly.

Binding was no longer a finishing step.

It had become a risk variable.

🔧 Bringing Binding Back In-House with SigLoch ZEN – Digital Perfect Binding Machine

The installation of the Bindwel SigLoch ZEN changed that equation.

By bringing binding in-house, L&M achieved:

- Near-zero binding wastage

- Improved spine strength and finish consistency

- Faster turnaround without external dependencies

- Better alignment between print and bind schedules

According to the company, overall book quality improved immediately-while delays and rework were virtually eliminated.

🛠 Why L&M Chose a Digital Perfect Binding Machine from Bindwel

While evaluating options in New Delhi and Mumbai, L&M reviewed several imported machines.

They ultimately decided against Chinese-made binders due to concerns around:

- Build quality

- Long-term reliability

- Service responsiveness

Bindwel stood out for three reasons:

- India-made engineering, designed for local operating realities

- Faster service response and remote troubleshooting support

- Proven robustness for short-run digital print environments

For a publisher, reliability mattered more than headline specifications.

⚙️ Features That Delivered Real Production Control

Rather than focusing on specifications alone, L&M evaluated outcomes.

They highlighted several aspects of the digital perfect binding machine that directly impacted quality:

- Three-roller gluing system for uniform adhesive application

- Driven side gluing, ensuring stronger page anchoring

- Consistent milling and spine preparation

- Stable cover nipping with controlled pressure

Finished books showed no spine reversal, no loose pages, and no customer rejections.

📖 A Demanding Job That Validated the Decision

One of the most notable projects completed on the SigLoch ZEN was the printing and binding of:

- 1,000 copies of the Bhagavad Gita (Marathi edition)

- 20-mm spine thickness

The job required precision, strength, and consistency-especially for a frequently handled religious title.

The company confirmed the digital perfect binding machine handled the job reliably, reinforcing confidence in its capability for demanding specifications.

📞 Service Support as an Operational Advantage

Beyond the machine itself, L&M rated Bindwel’s technical support highly.

They cited:

- Fast response times

- Effective issue resolution

- Proactive guidance during operations

Sharing feedback, Dhage stated:

“SigLoch Zen is an excellent addition to digital printing infrastructure and is exceeding our expectations and satisfaction. Our overall productivity has increased with almost zero wastages and increased print volume because of SigLoch Zen. The support from Team Bindwel is excellent with a fast response & resolution time. I am super delighted with SigLoch ZEN.”

📈 What This Means for Similar Publishers

For publishers handling:

- Short-run educational titles

- On-demand institutional books

- Multiple small batches with tight timelines

A digital perfect binding machine is not about scale.

It is about control.

L&M Innovative Publications demonstrates how bringing binding in-house can reduce uncertainty, improve quality, and protect delivery commitments-without expanding footprint or manpower.

🔍 Closing Note: A Digital Perfect Binding Machine That Matches Publishing Discipline

SigLoch ZEN did not change what L&M publishes.

It changed how confidently they deliver.

By installing a digital perfect binding machine designed for short-run reliability, L&M removed friction from the final stage of production-where delays are hardest to recover.

For publishers, that predictability is not optional.

It is operational insurance.

👉 Follow Bindwel on Facebook, LinkedIn, Twitter, Instagram and YouTube for stories from behind the book and updates from the festival. Be part of the journey that keeps reading alive.